Increase you tool life

Crafting Quality Precision Tools for Global Excellence

Increase Your Tool Life

- Use the proper sized Diamond.

- Mount the tools rigidly in the tool holder to reduce the vibration.

- Select the clamping length 'a'(Distance from diamond point to Fixture as short as possible to reduce the vibration. (Fig: 1)

- Incline Tool 10° to 15° to radius of wheel in the direction of wheel rotation to avoid dulling of the Diamond point. (Fig: 2)

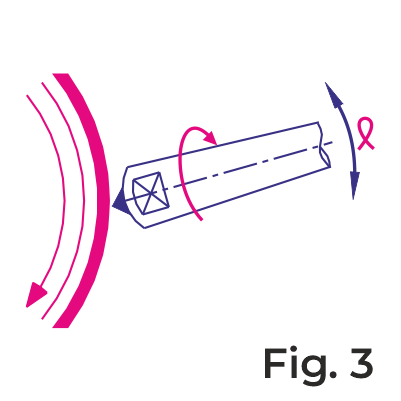

- Rotate the Diamond shank frequently by 90° to present new cutting edge. (Fig: 3)

- Always apply plenty of coolant while dressing, because Diamonds are very highly sensitive and can be destroyed by excessive heat generation (Fig: 4)

- For dry dressing do not apply the tool for a long continuous period. Allow the stone to cool naturally before using again. Do not cool the diamond by quenching.

- The depth of cut per dressing pass should not exceed the range of 0.02 to 0.03 mm. (20 to 30 micron).

- If possible, dress the wheel at a speed lower than normal grinding speed.

- Diamond is sensitive to shock and impact. It may be fractured or broken by striking any hard substance such as the bed of a machine or concrete floor. (Fig: 5)

- Protect and store the Diamond tool properly when not in use.