Struggling With Tool Wear? Switch to a PCBN Special Tool for Consistent Cutting Quality

If you’ve been battling inconsistent finishes, unexpected tool failures, or that frustrating drop in accuracy during machining, you’re not alone. Tool wear is one of the most expensive and annoying problems manufacturers deal with. One tiny slip in tool integrity and suddenly your perfect setup becomes a chain reaction of rework, downtime, and cost overruns.

But here’s the game-changer many production units overlook: a PCBN Special tool.

This tool isn’t just another cutting insert. It’s a long-term machining strategy one that actually works. Whether you’re cutting hardened steels, superalloys, or tough cast irons, a PCBN Special tool helps you maintain the consistency and cutting quality you expect every single day.

Let’s break down why this tool deserves your attention, how it transforms your machining performance, and why switching now can save you a lot more than just money.

Why Your Tools Are Wearing Out Faster Than Expected

Before we talk solutions, let’s talk problems the real ones you’re facing on the shop floor:

- Your tools lose sharpness too quickly during high-speed operations

- Cutting edges chip or break under heavy loads

- Surface finish becomes unpredictable

- Heat buildup causes premature tool failure

- You switch between multiple inserts for different stages of machining

- You waste time recalibrating cutters after micro-fractures

If any of these sound familiar, it’s often because the cutting tool material simply can’t handle the thermal, mechanical, and abrasive loads your operations demand.

This is exactly where a PCBN Special tool takes control.

PCBN Special Tool: What Makes It So… Special?

Let’s break this down without jargon.

PCBN stands for Polycrystalline Cubic Boron Nitride one of the hardest cutting materials in the world, second only to diamond.

But unlike natural diamond, PCBN performs brilliantly at high temperatures, high pressures, and high cutting speeds conditions where almost every other cutting material gives up.

- A PCBN Special tool is engineered to

- Handle extreme machining environments

- Deliver stable surface finishes at high speeds

- Resist heat damage and wear

- Reduce tool replacement frequency

- Improve dimensional accuracy

Where regular carbide tools struggle, a PCBN Special tool keeps cutting like it’s day one.

When Should You Use a PCBN Special Tool?

If one or more of these apply to you, you are the perfect candidate:

You machine hardened steels (HRC 45–70)

You work with cast irons, wear-resistant steels, sintered metals, or nickel alloys

You need precision under high-speed, continuous operations

You want a long-term tool with low cost-per-part

You want fewer setups and consistent performance

Industries using PCBN Special tools include automotive, aerospace, die & mold, defense, heavy machining, and energy components.

If you’re machining tough materials, switching to a PCBN Special tool isn’t a luxury it’s practically a requirement.

How a PCBN Special Tool Improves Cutting Quality Instantly

Here’s where things get interesting.

You’re not just reducing tool wear you’re transforming your machining process.

1. Exceptional Wear Resistance

The number one reason machinists switch to a PCBN Special tool is its unbelievable resistance to abrasive wear. Even at high cutting speeds or heavy depths of cut, PCBN maintains its edge for significantly longer cycles.

2. Heat? Not a Problem

Most tool failures start with heat. Carbide tools soften, crack, or lose sharpness.

A PCBN Special tool, however, remains stable under extreme temperatures. No softening. No deformation. No edge chipping.

3. Consistent Surface Finish

If surface finish is a priority, PCBN gives you the type of consistent quality that avoids rework. Smooth. Accurate. Repeatable.

4. Fewer Tool Changes

Less tool wear means fewer changeovers.

Fewer changeovers mean better productivity.

Better productivity means faster deliveries and happier customers.

5. High-Speed Compatibility

In today’s competitive environment, speed is everything.

A PCBN Special tool performs exceptionally well even at high speeds, which reduces machining time per part.

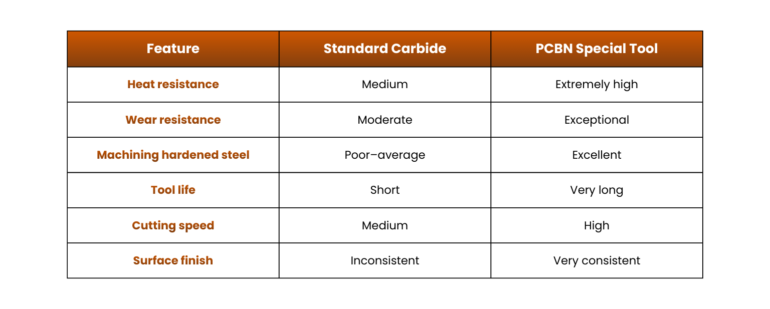

Why PCBN Outperforms Standard Carbide Tools

Let’s compare them directly in real-world shop floor terms:

The difference is massive. This is why shops that switch to a PCBN Special tool never go back.

Where Does the Diamond Dresser Come In?

Now you may wonder: “Why are we talking about Diamond Dresser when the hero here is PCBN?”

Simple. A Diamond Dresser plays a highly supportive but critical role.

✔ Dressing your grinding wheel

✔ Maintaining concentricity

✔ Ensuring better surface finish

✔ Enhancing the accuracy of tool preparation

A Diamond Dresser ensures your grinding wheels are always in the right condition to shape, finish, or resurface tools including PCBN.

Using a Diamond Dresser 3–4 times during wheel conditioning helps you maintain:

- Consistent wheel profile

- Better thermal control

- Enhanced cutting-edge preparation

- Improved repeatability

Paired together, a PCBN Special tool and a properly maintained wheel via a Diamond Dresser give you unmatched precision and long-term stability.

Long-Term Strategy: Why PCBN Is Not Just a Tool, but an Investment

This is where the long-term strategy comes into play.

If your aim is to:

- Reduce cost-per-part

- Improve machine uptime

- Boost productivity

- Enhance accuracy

- Win more machining projects

- Maintain consistent quality across months

Then the PCBN Special tool isn’t a consumable it’s a strategic upgrade.

Most shops that switch to a PCBN Special tool realize they’re not just cutting parts they’re improving their entire machining ecosystem.

Common Mistakes When Using PCBN (And How to Avoid Them)

Even the best tool can underperform if used incorrectly. Here are the mistakes you should avoid:

Using incorrect feed/speed combinations

PCBN performs best at high speeds not low.

Pairing with poorly dressed wheels

This is where a Diamond Dresser becomes essential.

Using it for the wrong materials

PCBN is perfect for hardened steels, cast irons, and superalloys but not soft, gummy metals.

Inconsistent coolant application

While PCBN can operate dry, consistent coolant helps stabilize temperature under specific operations.

Avoid these mistakes, and your PCBN Special tool will perform exactly the way it should.

How to Get the Best Performance Out of a PCBN Special Tool

Here’s a simple checklist:

- Use optimized high-cutting speeds

- Pair with a wheel conditioned using a Diamond Dresser

- Ensure rigid fixturing

- Avoid low feed rates

- Use stable spindle speeds

- Monitor heat levels

Follow these guidelines, and your PCBN Special tool will give you long, reliable performance.

Is Switching to a PCBN Special Tool Worth It?

If you’re tired of:

- Tool wear that keeps ruining your schedule

- Inconsistent surface finish

- Rising production costs

- Tools breaking at the worst possible time

then YES switching to a PCBN Special tool is one of the smartest moves you can make.

It gives you:

✔ Stability

✔ Precision

✔ Longevity

✔ Reliability

✔ Speed

When combined with the supportive role of a Diamond Dresser, you get a machining setup designed for long-term, predictable, high-quality performance.

Your machining deserves tools that work with you, not against you. A PCBN Special tool ensures exactly that.