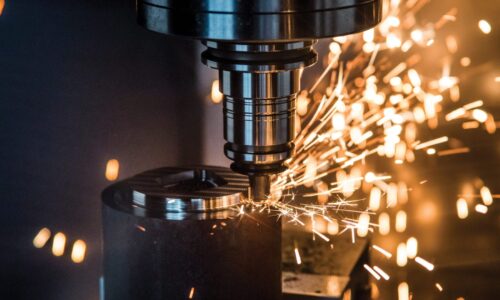

How PCD Endmills Improve Tool Life & Reduce Costs

PCD endmills have become a game-changer for manufacturers who constantly struggle with tool wear, unpredictable machining performance, and rising production costs. If you’ve ever faced these issues, you already know how challenging it is to maintain consistency on the shop floor. Everything may look perfect during programming correct spindle speed, proper coolant strategy, ideal material grade but the final output still ends up rough, inaccurate, or completely out of tolerance. In most cases, the real issue isn’t the machine or even the operator; it’s the tool. And this is exactly where a PCD endmill makes all the difference.

Polycrystalline Diamond (PCD) tools have transformed modern machining, especially for high-precision industries where every micron matters. Whether you’re cutting aluminum alloys, composites, copper, brass, metal matrix materials, or abrasive non-ferrous components, the right PCD endmill can significantly extend tool life, improve surface finish, and reduce overall machining expenses.

Let’s break down how it works and why more manufacturers are switching to PCD tooling to stay competitive.

The Real Problem: Traditional Tools Wear Out Faster

Machining non-ferrous materials has always been challenging. Standard carbide tools often:

- Wear out quickly due to material abrasiveness

- Lose cutting edge sharpness

- Generate heat at high speeds

- Produce inconsistent surface finishes

- Require frequent tool changes

- Cause downtime and production delays

Every tool change comes with a cost machine stoppage, repositioning, re-calibration, and risk of errors. Multiply this across hundreds of parts, and suddenly your production cost shoots through the roof.

So the question is obvious: How do you maintain precision and reduce tool wear at the same time?

What Makes a PCD Endmill Different?

A PCD endmill is crafted using sintered diamond particles bonded under high temperature and pressure. This makes it extremely hard second only to natural diamond.

But hardness alone doesn’t define its performance. The real magic lies in:

- Very low friction during cutting

- Exceptional heat resistance

- Long-lasting sharp cutting edges

- Ability to run at extremely high speeds (VMC/HMC)

PCD tooling allows industries to machine material faster, smoother, and more precisely with less wear and tear on the spindle.

How PCD Endmills Improve Tool Life

Tool life isn’t just about longevity it’s about predictable, stable performance. Here’s how a PCD endmill dramatically increases tool life:

1. Hardness That Outperforms Carbide

PCD is 5–7 times harder than carbide. This means the cutting edge remains sharp even after long cycles of continuous machining.

2. Resistance to Abrasive Wear

Materials like MMC, graphite, carbon fiber, ceramics, and abrasive composites destroy carbide tools quickly. A PCD endmill maintains integrity even under highly abrasive conditions.

3. Better Heat Dissipation

Low thermal conductivity in carbide tools leads to heat buildup. PCD, on the other hand, dissipates heat efficiently, preventing premature tool failure.

4. Low Friction = Lower Cutting Forces

Less friction reduces:

- Vibration

- Chipping

- Cratering

- Built-up edge formation

This helps the tool last significantly longer while maintaining stability.

5. Stable Performance at High RPM

PCD endmills thrive in high-speed machining environments. Even at aggressive feed rates, they stay sharp, making them ideal for industries that need speed and accuracy.

How PCD Endmills Reduce Manufacturing Costs

Reducing cost isn’t just about buying a cheaper tool it’s about reducing per-part machining cost. A PCD endmill helps achieve this in several ways:

1. Fewer Tool Changes = Less Downtime

When a tool lasts longer, your machine keeps running.

This directly reduces:

- Setup time

- Downtime

- Calibration errors

- Labor cost

A single tool that runs for hours without replacement saves significant operational cost.

2. Faster Cutting Speeds

PCD supports:

- High RPM

- High feed rates

- Greater material removal

This means you can produce more parts in less time boosting overall productivity.

3. Superior Surface Finish

A PCD endmill often eliminates the need for secondary finishing operations like:

- Polishing

- Grinding

- Deburring

Less finishing = less time, less cost.

4. Improved Dimensional Accuracy

PCD tools hold tolerances consistently across long production runs, enabling you to reduce scrap rates and rework.

5. Lower Spindle Load

Reduced cutting forces minimize wear on the machine itself.

This helps extend spindle life and reduce long-term maintenance costs.

Applications Where PCD Endmills Deliver Maximum Benefits

PCD tooling is a game-changer for industries working with non-ferrous and abrasive materials.

Aerospace

- Aluminum structural components

- Honeycomb materials

- Composite skins

Automotive

- EV motor housings

- Brake components

- Aluminum transmission parts

Electronics

- Copper heat sinks

- PCB materials

- Silicon and ceramic components

General Manufacturing

- Acrylic components

- Fiber-reinforced plastics

- Graphite mold making

Anywhere precision meets production volume PCD wins.

PCD Endmill vs. Carbide: A Quick Comparison

Even though a PCD endmill has a higher upfront price, the long-term return is far superior.

- Hardness:

Carbide offers good hardness, but a PCD endmill is significantly harder—almost approaching natural diamond. This gives PCD tools a major advantage in durability and wear resistance. - Tool Life:

Carbide tools perform well for basic machining, but a PCD endmill delivers 10 to 50 times longer tool life depending on the material and application. - Surface Finish:

Carbide tools often leave a moderate finish that may require polishing. A PCD endmill produces an almost mirror-like surface straight from the machine, which means reduced finishing time. - Material Suitability:

Carbide works well for steels and general metals, but struggles with abrasive or non-ferrous materials. A PCD endmill is specifically designed for aluminum, composites, MMC, graphite, ceramics, copper, and other non-ferrous materials. - Speed Capability:

Carbide has limitations when running at high RPMs. In contrast, a PCD endmill thrives at extreme speeds, allowing faster cycle times and improved productivity. - Cost Efficiency:

While carbide tools are cheaper to buy, they wear out quickly. A PCD endmill has a higher upfront cost but drastically lower cost per component thanks to longer life, fewer tool changes, and reduced downtime.

Where PCBN Special Tools Fit In

While PCD endmills are perfect for non-ferrous materials, there are certain applications where you need a more robust solution; this is where a PCBN Special tool excels.

PCBN (Polycrystalline Cubic Boron Nitride) is specifically designed for:

- Hardened steel machining

- High-temperature alloys

- Cast iron

- Powder metallurgy components

A PCBN Special tool delivers:

- Excellent thermal stability

- Resistance to chemical wear

- Unmatched performance on hardened materials

- Extended tool life compared to carbide or ceramic tools

In many mixed-material machining environments, manufacturers use PCD endmills for aluminum or composites and a PCBN Special tool for hardened steel or cast iron within the same production line.

This combination helps maintain consistency, reduce cycle time, and minimize tool cost.

Why Manufacturers Are Shifting to PCD Endmills Now More Than Ever

Here’s what’s driving the industry shift:

Demand for high-precision parts: Tolerance requirements are now tighter than ever.

Increase in composite & non-ferrous materials: Especially with EV, aerospace, and electronics growth.

Need for faster production: High-speed machining is becoming the new standard.

Rising cost of downtime: Every minute the machine stops, money is lost.

Pressure to reduce scrap: Rework is expensive and often impossible on specialized materials.

The PCD endmill has become the go-to solution because it checks every box: accuracy, speed, tool life, and cost savings.

How to Choose the Right PCD Endmill for Your Application

Here’s what you should consider:

1. Material Type

Different materials require specific PCD geometries and grades.

2. Required Surface Finish

Higher finish = sharper cutting edges and polished flutes.

3. Tool Diameter & Flute Count

More flutes = better for finishing

Fewer flutes = better chip evacuation

4. Machine RPM Capability

PCD thrives at high speeds, so spindle capability matters.

5. Operation Type

- Slotting

- Profiling

- Facing

- Contour cutting

- Pocketing

Each requires a specific design.

6. Expected Production Volume

Higher volume = more benefit from PCD tooling.

Conclusion

If your machining process demands accuracy, consistency, and long-term cost savings, a PCD endmill is one of the smartest investments you can make. It reduces wear, minimizes downtime, improves surface finish, and delivers reliable performance at high speeds.

And when your application involves hardened steels or high-temperature alloys, pairing your PCD tools with a PCBN Special tool gives your production line the complete cutting advantage.

In today’s competitive manufacturing world, the shops that adopt smarter tooling solutions are the ones that stay ahead. And for non-ferrous machining, the PCD endmill continues to prove why it’s the industry’s first choice.