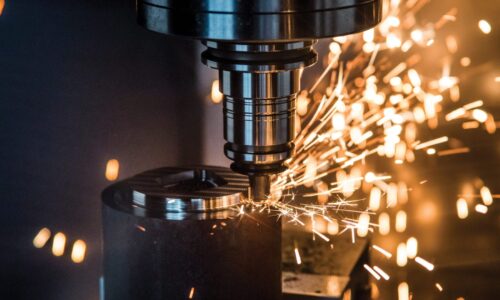

Upgrade Your Cutting Performance with PCBN Inserts and PCD Tools

If you’ve ever dealt with tool wear, unpredictable cutting performance, or inconsistent surface finish, you already know how difficult it is to maintain accuracy in machining. Everything may look perfect during programming the right feeds, the correct spindle speed, even ideal material selection but the final result still doesn’t match the expected quality.

In most cases, the real issue isn’t the machine or the operator. It’s the tool.

And this is exactly where PCBN inserts and PCD tools step in as game-changing solutions for modern machining setups. These cutting tools are engineered for precision, tool life, and consistency, three things every manufacturer depends on but often struggles to achieve.

In this detailed guide, we’ll explore how PCBN inserts elevate hard-material cutting, how PCD tools support high-accuracy machining, and why combining the two creates a superior cutting strategy for long-term performance.

Understanding PCBN Inserts: What Makes Them So Powerful?

PCBN inserts (Polycrystalline Cubic Boron Nitride) are among the hardest cutting materials used in machining. They come second only to diamond in hardness, which makes them ideal for cutting extremely tough, hardened materials that conventional carbide inserts simply cannot handle.

Here’s what makes PCBN inserts special:

- Exceptional wear resistance

- High thermal stability

- Ability to machine hardened materials smoothly

- Long tool life even under aggressive cutting conditions

- Consistent surface finish across long production cycles

The unique advantage of PCBN inserts is their ability to maintain sharpness and dimensional stability even at high temperatures. This reduces the need for frequent tool changes and ensures uninterrupted machining a key factor in achieving predictable productivity.

Where PCBN Inserts Offer the Biggest Advantage

PCBN inserts are ideal for cutting applications where:

- Hard materials need finishing

- Carbide tools wear out too fast

- Dimensional accuracy is critical

- High surface finish is required

- Thermal load is high

- Long machining cycles are expected

Because of their unmatched hardness and wear resistance, PCBN inserts are perfect for hard turning, continuous cutting, and high-speed operations where lesser tools fail.

How PCBN Inserts Improve Cutting Performance

When you upgrade to PCBN inserts, several improvements become immediately noticeable:

1. Dramatic Reduction in Tool Wear

PCBN can withstand extreme temperatures and pressure, meaning it holds its cutting edge far longer than carbide. This gives you stable performance, less downtime, and fewer tool changes.

2. More Accurate and Predictable Finishes

Consistency is one of the biggest strengths of PCBN inserts. They help you achieve predictable surface finishes across long machining runs without dimensional drift.

3. Higher Cutting Speeds

Because PCBN handles heat exceptionally well, it allows you to machine at higher speeds without sacrificing quality. Faster operations lead to better output.

4. Lower Cost Per Component

Even though PCBN inserts cost more upfront, their long life and reduced downtime make them more economical in the long run.

5. Better Thermal Control

PCBN’s heat resistance reduces thermal cracks, ensuring smoother cutting and preventing damage to the workpiece.

Upgrading to PCBN inserts is not just a tooling upgrade it’s a productivity upgrade.

Understanding PCD Tools: Precision for Non-Ferrous and Soft Materials

Now that we’ve covered PCBN inserts, let’s talk about how PCD tools (Polycrystalline Diamond tools) complement them.

Where PCBN handles extremely hard materials, PCD tools excel in machining:

- Aluminum

- Copper

- Brass

- Magnesium

- Plastics

- Composites

- Graphite

- Other non-ferrous materials

The biggest advantage of PCD tools is their ability to deliver smooth, mirror-like finishes at very high cutting speeds. Their extreme hardness and low friction make them ideal for applications where carbide tools cannot maintain consistency.

Key Benefits of PCD Tools

1. Long-Lasting Sharpness

PCD tools maintain a razor-sharp edge much longer than carbide tools. This reduces wear and ensures high-precision cuts.

2. Superior Surface Finish

PCD produces an extremely smooth surface, reducing the need for secondary finishing operations.

3. High-Speed Cutting Capability

PCD tools can operate at very high cutting speeds, boosting productivity.

4. Lower Heat Generation

The natural lubricity of PCD reduces friction, lowering heat buildup and tool damage.

5. Reliable Dimensional Accuracy

Because PCD tools resist wear and chipping, they maintain consistent tolerance across long machining batches.

PCBN Inserts + PCD Tools: A Complete Cutting Solution

When used together, PCBN inserts and PCD tools create a cutting system capable of handling both extremes:

- PCBN inserts for ultra-hard materials

- PCD tools for soft, abrasive, or non-ferrous materials

This combination covers a wide range of machining requirements and provides stability, precision, and long-term performance.

Why this combination works so well:

- PCBN handles heat from hard-turning

- PCD handles delicate, high-speed finishing

- Both offer long tool life

- Both improve part accuracy

- Both reduce production downtime

This synergy gives manufacturers an edge in overall machining performance.

Signs That You Should Upgrade to PCBN Inserts or PCD Tools

If you’re experiencing any of the following issues, it’s time to consider upgrading your cutting setup:

- Rapid tool wear

- Dimensional inconsistency

- Burn marks or thermal cracks

- Poor surface finish

- Frequent tool changes

- Long cycle times

- Vibrations or chatter

- High tooling costs

Often, these problems disappear when switching to PCBN inserts for hard materials or PCD tools for non-ferrous materials.

How to Select the Right Grade of PCBN Inserts

Choosing the right grade of PCBN inserts depends on:

The hardness of the material: Harder materials require higher PCBN content.

Continuous or interrupted cutting:Interrupted cuts require tougher PCBN grades.

Required surface finish: Smoother finishes call for a finer, sharper PCBN grade.

Speed and feed: High-speed machining benefits from thermally stable PCBN inserts.

Workpiece geometry: Complex shapes may require specific insert geometries for better stability.

If you match the PCBN grade correctly, your tool performance becomes far more predictable.

How to Choose the Right PCD Tool

Choosing the right PCD tools depends on:

Workpiece material: Aluminum requires sharp tools, while composites require abrasion-resistant tools.

Surface finish requirement: Tighter finish → sharper PCD edges.

Machining speed: High speeds require stable and strong PCD edges.

Tool geometry: Correct rake, relief angle, and nose radius are key for perfect finishing.

5 Practical Tips to Maximize Tool Life

Whether you are using PCBN inserts or PCD tools, these tips will help improve tool life:

1. Maintain stable cutting conditions

Vibrations and chatter reduce tool life quickly.

2. Use proper coolant flow

Even though PCBN and PCD handle heat well, good coolant ensures consistent performance.

3. Keep the toolholder rigid

Weak toolholding results in dulling and edge chipping.

4. Avoid sudden cutting interruptions

Interrupted cuts damage edges faster.

5. Use correct insert geometry

Sharp edges improve finishing, while stable edges improve tool life.

Conclusion

Upgrading your machining setup with PCBN inserts and PCD tools is one of the most effective ways to boost cutting performance, improve accuracy, and reduce long-term costs. PCBN inserts deliver exceptional results on hard materials, while PCD tools offer unmatched precision for non-ferrous and soft materials.

Together, they give you:

- Longer tool life

- Higher accuracy

- Better surface finish

- Reduced downtime

- Greater productivity

- Lower cost per part

If you’re looking for consistent machining performance, investing in high-quality PCBN inserts and PCD tools is a decision that pays off every single day on the shop floor.