PCBN Inserts Distributors in India:

In precision manufacturing, consistent machining performance is never accidental. It is the result of carefully selected machines, optimized processes, skilled operators and equally important reliable cutting tool supply. As machining tolerances become tighter and production demands increase, manufacturers must rely on dependable Distributors in India who can support advanced tooling requirements with consistency and technical understanding.

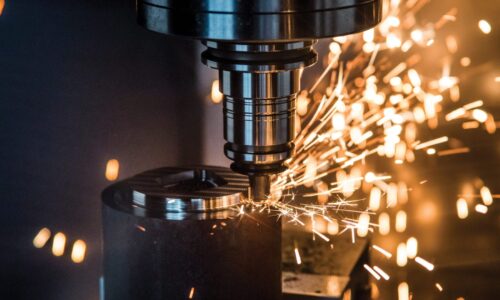

For applications involving hardened materials, high cutting temperatures, and demanding surface finish requirements, PCBN Inserts have become an essential solution. However, the performance of these advanced tools depends not only on their design and material quality, but also on the expertise and reliability of the distributors supplying them.

An overview of how professional Distributors in India contribute to stable machining operations, what manufacturers should consider when selecting a tooling partner, and why distributor capability plays a vital role in achieving long-term productivity and accuracy.

The Role of Distributors in India in Modern Manufacturing

Today’s manufacturing environment places significant pressure on machining operations to deliver precision, repeatability, and efficiency. Cutting tools are no longer consumables, they are performance drivers. This shift has elevated the importance of knowledgeable Distributors in India who understand both tooling technology and real-world machining conditions.

Effective distributors act as a bridge between advanced tool manufacturing and shop-floor application. They ensure manufacturers receive the correct tool grade, geometry, and edge preparation for their specific machining requirements. This role becomes even more critical when working with advanced materials and hardened components.

By partnering with experienced Distributors in India, manufacturers gain access to consistent tool quality, application guidance, and dependable supply elements that directly impact productivity and cost control.

Understanding PCBN Inserts in Precision Machining

PCBN Inserts are engineered cutting tools designed for machining hardened ferrous materials and wear-resistant alloys. Known for their extreme hardness and thermal stability, they enable manufacturers to perform hard turning operations that would otherwise require grinding.

Key Characteristics of PCBN Inserts

- Excellent wear resistance at high cutting speeds

- Stability under elevated temperatures

- Ability to machine hardened materials with consistent accuracy

- Superior surface finish when applied correctly

Because PCBN Inserts are application-specific, their success depends heavily on correct selection and usage. This is where the technical competence of Distributors in India becomes essential, as improper grade selection or cutting parameters can significantly affect tool life and machining results.

Why Manufacturers Depend on Reliable Distributors in India

Choosing the right tooling partner is a strategic decision. Reliable Distributors in India support manufacturing operations in several critical ways:

Consistency in Tool Performance

Uniform insert quality across batches ensures predictable machining outcomes. Established distributors maintain strict quality standards to avoid variation in performance.

Technical Application Support

Experienced Distributors in India provide guidance on cutting parameters, insert selection, and process optimization helping manufacturers achieve stable and repeatable results.

Supply Reliability

Production schedules depend on uninterrupted tool availability. Professional distributors maintain inventory levels that support both planned production and urgent requirements.

Long-Term Process Stability

By supplying consistent tooling solutions, Distributors in India help manufacturers reduce downtime, minimize tool-related issues, and maintain process control.

Applications Supported by Advanced Machining Requirements

Manufacturers working with hardened materials and precision components require cutting tools that deliver stability, accuracy, and repeatable performance. Across a wide range of machining environments, Distributors in India play a critical role in ensuring access to high-quality tooling solutions that meet demanding process conditions.

Precision Turning of Hardened Components

Machining hardened parts such as shafts, gears, and wear-resistant components requires tools capable of maintaining edge integrity under high temperatures and cutting loads. Professional Distributors in India support these requirements by supplying inserts designed for consistent performance in hardened turning applications.

High-Accuracy Bearing and Rotational Components

Applications involving bearing races and similar precision parts demand tight tolerances and superior surface finish. Reliable Distributors in India ensure consistent availability of cutting solutions, including PCBN Inserts, that support stable machining and dimensional accuracy in high-precision operations.

Machining of High-Strength and Engineered Materials

Components produced from high-strength steels and engineered alloys require specialized cutting tools with excellent thermal resistance and wear stability. Knowledgeable Distributors in India help manufacturers select tooling suited for such challenging machining conditions, ensuring process reliability and repeatable output.

Tool, Mold, and Die Machining Applications

Machining hardened tool steels for molds, dies, and precision tooling often requires alternatives to traditional grinding. Experienced Distributors in India provide access to advanced turning solutions that help improve productivity, reduce secondary operations, and maintain consistent accuracy.

Selecting the Right Distributors in India: Key Considerations

Not all distributors offer the same level of capability. When evaluating Distributors in India, manufacturers should consider the following factors:

Technical Knowledge and Experience

A strong understanding of machining applications, material behavior, and tooling geometry is essential when dealing with advanced cutting tools.

Quality Assurance

Reliable distributors ensure consistent manufacturing standards and traceability for PCBN Inserts, minimizing the risk of variation in performance.

Application-Focused Approach

Professional Distributors in India focus on solving machining challenges rather than simply supplying products.

Long-Term Support

A dependable distributor builds partnerships based on continuous improvement, process optimization, and technical collaboration.

Avoiding Common Mistakes When Choosing Distributors in India

Manufacturers sometimes face performance issues due to avoidable sourcing mistakes.

- Selecting distributors based solely on price rather than technical capability

- Ignoring the importance of application support

- Working with suppliers who lack consistency in quality and availability

Choosing experienced Distributors in India helps avoid these risks and ensures stable machining performance over time.

The Growing Importance of Distributors in India

As manufacturing complexity increases, the role of Distributors in India continues to expand. They are no longer just supply channels, but strategic partners who contribute directly to machining efficiency and quality outcomes.

With advanced tooling solutions such as PCBN Inserts, distributor expertise becomes a critical factor in unlocking the full potential of the cutting tool and the machine itself.

Partnering with the Right Distributors in India

Precision machining depends on more than just machines and materials it depends on the reliability of the tooling ecosystem. Partnering with capable Distributors in India ensures access to consistent, application-optimized cutting tools that support accuracy, productivity, and long-term process stability.

For manufacturers working with hardened materials and demanding machining requirements, choosing experienced distributors for PCBN Inserts is a key step toward achieving dependable performance and operational efficiency.