PCD Grewing Tool to Improve Stone Finishing the Easy Way

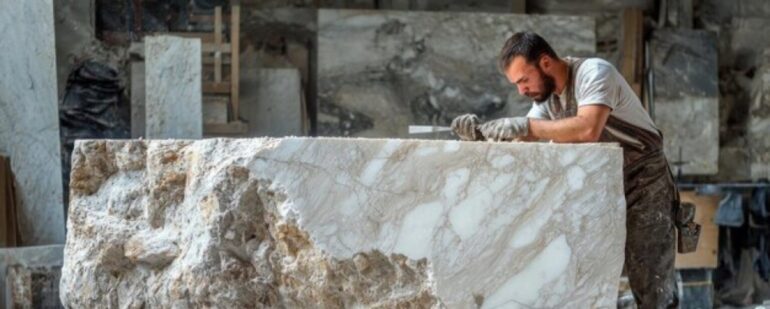

Stone fabrication is a craft that rewards precision and consistency. Every slab that passes through a machine carries expectations of smooth edges, uniform grooves, clean finishes, and minimal material loss. Yet many stone processors quietly struggle with uneven finishing, excessive tool wear, and rising production costs. The challenge is not always the machine or the operator. More often, it comes down to the tool doing the work.

This is where the PCD grewing tool quietly changes the game.

Instead of forcing fabricators to adjust processes again and again, the right tooling simplifies the job itself. When stone finishing becomes easier, faster, and more predictable, productivity naturally improves and so does profitability.

Why Stone Finishing Often Becomes a Bottleneck

Stone may look solid and uniform from the outside, but every fabricator knows how unpredictable it can be. Granite, marble, quartz, and engineered stone all behave differently during cutting and grooving. Even within the same slab, hardness and grain structure can vary.

Common challenges faced during stone finishing include:

- Rough or uneven grooves

- Edge chipping near finished surfaces

- Frequent tool replacement

- Heat generation affecting surface quality

- Inconsistent results across batches

When finishing quality drops, it impacts downstream processes like polishing, fitting, and installation. This is why finishing tools must be stable, durable, and precise qualities that define a PCD grewing tool.

What Makes a PCD Grewing Tool So Effective

A PCD grewing tool is designed using polycrystalline diamond, a material known for its exceptional hardness and wear resistance. In stone fabrication, this directly translates into smoother finishes and longer tool life.

Unlike conventional tools that degrade quickly when exposed to abrasive stone surfaces, a PCD grewing tool maintains its cutting geometry for extended production runs. This stability is what makes stone finishing easier not just technically, but operationally.

Key advantages include:

- Clean, uniform grooves with minimal chipping

- Consistent performance even on hard stone materials

- Reduced need for frequent tool changes

- Lower heat buildup during operation

For stone fabricators focused on quality and efficiency, these benefits are not optional they are essential.

Making Stone Finishing Easier Without Changing Your Process

One of the biggest misconceptions in stone fabrication is that better results require complex process changes. In reality, the right tool often delivers improvement without altering machine settings or workflows.

A PCD grewing tool fits seamlessly into existing setups while delivering immediate improvements in finishing quality. Operators notice smoother cuts, reduced vibration, and better control during grooving operations. Over time, this consistency reduces operator fatigue and machine stress.

When finishing becomes predictable, planning production becomes easier. Deadlines are met, rejection rates fall, and customer satisfaction improves.

Role of Jain Diamond Tool in Stone Fabrication

Jain Diamond Tool understands that stone fabrication is not just about cutting it’s about finishing that adds value to the final product. As an experienced diamond tool manufacturer, the company designs tools that address real shop-floor challenges rather than theoretical performance.

Their PCD grewing tool solutions are developed with:

- Application-specific tool geometry

- Optimized diamond placement

- Strong bonding for extended life

- Compatibility with stone fabrication machinery

This practical approach ensures that fabricators receive tools that work reliably under actual production conditions.

Consistency Matters More Than Speed

Many fabricators chase higher speeds to improve output, but speed without control often leads to quality issues. A PCD grewing tool allows fabricators to maintain consistent finishing quality even at optimized cutting speeds.

Because the tool edge remains stable for longer durations, groove dimensions stay uniform across multiple slabs. This consistency is especially valuable in large projects where visual and dimensional uniformity is critical.

When every piece meets the same standard, finishing becomes a strength rather than a risk.

Supporting Tools That Improve Overall Results

Stone finishing does not rely on a single tool alone. Supporting tools play an important role in maintaining performance across the production cycle.

A Multipoint Diamond Dresser is essential for conditioning grinding wheels used during stone finishing. By keeping the wheel sharp and properly profiled, it ensures that finishing operations remain smooth and controlled. When paired with a PCD grewing tool, the overall process becomes more stable and predictable.

As a trusted diamond tool manufacture, Jain Diamond Tool provides solutions that work together rather than in isolation, helping fabricators achieve consistent results throughout their operations.

Reducing Costs Without Compromising Quality

One of the most practical benefits of using a PCD grewing tool is cost control. While the initial investment may appear higher than conventional tools, the long-term savings are significant.

Fabricators benefit from:

- Fewer tool replacements

- Reduced downtime

- Lower scrap and rework rates

- Improved machine utilization

Over time, the cost per finished slab drops, making operations more competitive and scalable. Quality improves not because of additional effort, but because the tool performs reliably.

Ideal Applications in Stone Fabrication

A PCD grewing tool is widely used in stone fabrication for:

- Edge grooving of granite and marble slabs

- Slotting operations in quartz surfaces

- Precision channel creation for countertops

- Decorative groove finishing in architectural stone

Its versatility allows it to serve both small workshops and large production facilities with equal effectiveness.

Why Ease of Finishing Is a Competitive Advantage

Customers may never see the tool used in fabrication, but they immediately notice the finish. Clean grooves, smooth edges, and uniform surfaces communicate quality without explanation.

When finishing becomes easy, fabricators gain confidence in their output. This confidence reflects in faster delivery, fewer complaints, and stronger business relationships.

A PCD grewing tool supports this advantage by removing uncertainty from one of the most critical stages of stone processing.

Choosing the Right Partner for Diamond Tooling

Tools alone do not guarantee results. The expertise behind the tool matters just as much. Working with a reliable diamond tool manufacture ensures access to technical guidance, consistent quality, and tools designed for long-term use.

Jain Diamond Tool’s experience in diamond tooling allows stone fabricators to move beyond trial-and-error approaches and adopt solutions built for reliability and performance.

Conclusion

Stone finishing does not have to be complicated, unpredictable, or expensive. With the right tooling in place, it becomes a controlled, repeatable process that adds value to every slab produced.

A PCD grewing tool simplifies stone finishing by delivering consistent quality, longer tool life, and smoother operations. Supported by complementary solutions like a Multipoint Diamond Dresser and backed by a trusted diamond tool manufacture, it becomes an essential part of modern stone fabrication.

For fabricators looking to improve finishing quality without increasing complexity, the solution is clear start with the right tool, and let performance speak for itself.