How to Choose the Right Automotive Cutting Tool Supplier for Cost-Effective and High-Quality Production

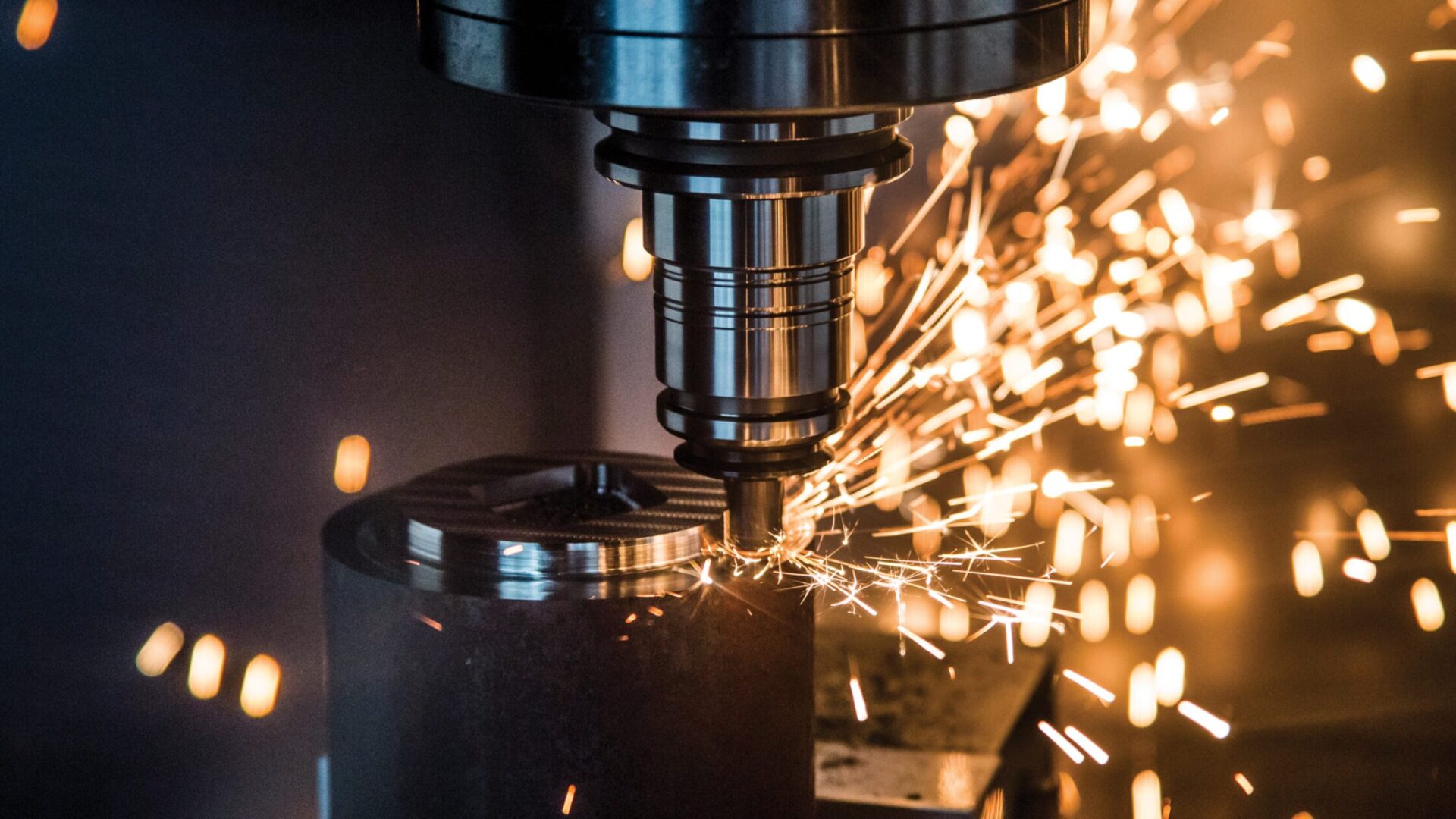

If you are working in the automotive manufacturing industry, you already know one thing production quality and cost control go hand in hand. But many companies focus only on machines and technology, while one critical factor is often overlooked: the cutting tools and, more importantly, the supplier behind those tools. Choosing the right automotive cutting tool supplier is not just about purchasing tools.

It directly impacts production cost, tool life, downtime, surface finish quality, and overall manufacturing efficiency.

Many businesses only compare the automotive cutting tool price, but real value comes from performance, consistency, and technical support. In this blog, we will help you understand how to choose the right supplier in a simple and practical way even if you are not from a technical background.

Why Choosing the Right Automotive Cutting Tool Supplier Matters

A reliable automotive cutting tool supplier does more than deliver tools. They help improve production performance and reduce hidden costs.

A good supplier ensures:

- Consistent tool quality

- Stable production output

- Lower tool breakage risk

- Better machining accuracy

- Long-term cost savings

Many manufacturers focus only on the initial automotive cutting tool price, but cheaper tools can increase replacement frequency and production downtime. That’s why supplier selection is a strategic decision.

Understanding Automotive Cutting Tool Price vs Actual Value

When evaluating automotive cutting tool price, it is important to understand what you are paying for.

A slightly higher price can mean:

- Longer tool life

- Better coating technology

- More consistent material quality

- Technical support and customization

The right automotive cutting tool supplier will always explain cost vs performance instead of just offering the lowest price. Smart buyers compare lifecycle cost, not just purchase cost.

Signs of a Reliable Automotive Cutting Tool Supplier

1. Industry Experience

An experienced automotive cutting tool supplier understands automotive component challenges like hard materials, tight tolerances, and high-volume production.

2. Product Range

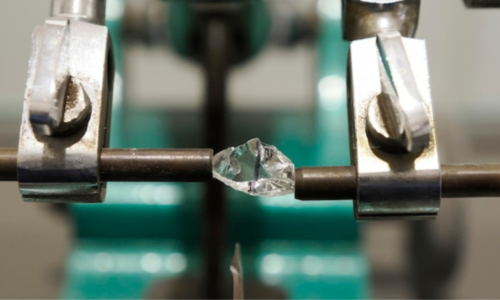

A good supplier should provide multiple solutions including abrasives tools, dressing tools, and special inserts depending on application needs.

3. Technical Support

Suppliers should guide on tool selection, cutting parameters, and optimization.

4. Consistent Pricing Structure

Transparent automotive cutting tool price without sudden fluctuations builds trust.

How Tool Technology Impacts Automotive Manufacturing

Modern automotive production uses advanced tool technologies like:

- Chip breaking inserts – Help control chip flow and improve surface finish

- PCD grewing tool – Used for high precision edge finishing

- Roller Dressers – Help maintain grinding wheel accuracy

- abrasives tools – Used for finishing and surface preparation

A strong automotive cutting tool supplier will help you choose the right technology based on production needs, not just tool availability.

Common Problems When Choosing the Wrong Supplier

Choosing suppliers only based on low automotive cutting tool price can lead to:

- Frequent tool failure

- Surface finish variation

- Increased machine downtime

- Higher long-term cost

- Inconsistent batch quality

This is why selecting the right automotive cutting tool supplier is critical for stable automotive production.

How to Compare Automotive Cutting Tool Suppliers

When comparing suppliers, consider:

Quality Consistency:-

Ask for batch consistency data and performance reports.

Application Support

Does the automotive cutting tool supplier provide technical guidance?

Customization Capability

Automotive manufacturing often needs customized tools.

Delivery Reliability

Production delays cost more than tool price differences.

Long-Term Automotive Cutting Tool Price Stability

Stable pricing helps production planning and budgeting.

Cost Optimization Strategies Using the Right Supplier

Working with a strong automotive cutting tool supplier helps you reduce cost through:

- Tool life optimization

- Reduced rejection rates

- Faster machining cycles

- Lower machine wear

Instead of choosing the lowest automotive cutting tool price, focus on total production cost per component.

Future Trend: Smart Supplier Partnerships

Modern automotive manufacturers are moving toward long-term partnerships instead of transactional buying.

A strategic automotive cutting tool supplier helps with:

- Process improvement

- Tool innovation

- Cost reduction planning

- New material machining solutions

This approach improves both productivity and profitability.

Conclusion

Choosing the right automotive cutting tool supplier is a business decision, not just a purchase decision. While automotive cutting tool price is important, real value comes from performance, reliability, and support.

Companies that focus only on tool price often face higher hidden costs. But companies that select the right supplier build stronger production systems and long-term cost savings.

If your goal is to improve production quality, reduce downtime, and maintain consistent output, choosing the right supplier is one of the smartest investments you can make.