EV Component Tooling Partner for High-Quality Manufacturing

The electric vehicle industry is growing faster than ever. New manufacturers are entering the market, production demand is increasing, and competition is becoming stronger. But behind every successful EV manufacturer, there is one common factor strong manufacturing support and reliable tooling solutions.

Many companies focus heavily on machinery and automation but often overlook the importance of choosing the right EV component tooling partner. The truth is, tooling quality directly affects production accuracy, surface finish, cycle time, and overall manufacturing cost.

While many buyers initially compare EV component tooling cost, the real impact of tooling goes far beyond the price. The right partner helps improve production consistency, reduce downtime, and increase tool life all of which improve profitability.

In this blog, we will explain in simple terms how to choose the right tooling partner and why this decision plays a major role in EV manufacturing success.

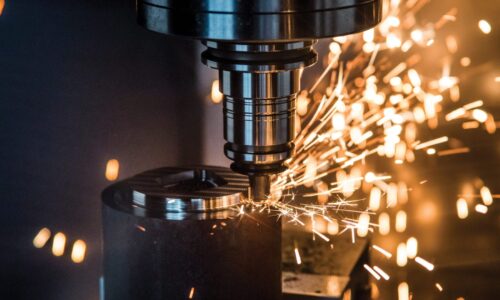

Why Tooling Quality Matters in EV Manufacturing

EV components require extremely high precision. Many EV parts are made from advanced alloys, lightweight materials, and composite structures that are harder to machine than traditional automotive components.

A reliable EV component tooling partner ensures:

- Stable machining performance

- Consistent dimensional accuracy

- Better surface finish quality

- Reduced tool wear and breakage

- Lower rejection rate

Many manufacturers try to reduce upfront cost by choosing lower EV component tooling cost options. However, low-quality tooling often increases long-term manufacturing cost due to frequent replacements and production delays.

Understanding EV Component Tooling Cost vs Manufacturing Value

When evaluating EV component tooling cost, it is important to consider total production value rather than just purchase price.

The right EV component tooling partner focuses on:

- Tool life performance

- Machining efficiency

- Consistent batch quality

- Reduced downtime

- Lower cost per component

Sometimes, slightly higher tooling cost results in lower overall production expense. Smart EV manufacturers always evaluate lifecycle cost instead of just initial tool cost.

Key Qualities of a Reliable EV Component Tooling Partner

1. Industry Experience

An experienced EV component tooling partner understands EV-specific challenges such as motor component machining, battery housing precision requirements, and lightweight material processing.

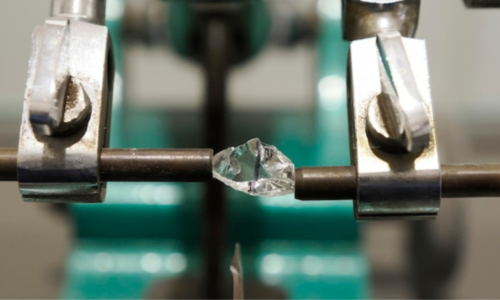

2. Custom Tooling Capability

EV manufacturing often needs customized tooling solutions. The right partner can design tools based on specific production needs.

3. Material Knowledge

Different EV components use different materials. A strong EV component tooling partner provides tooling solutions optimized for each material type.

4. Transparent EV Component Tooling Cost Structure

Clear pricing and performance justification help manufacturers plan production budgets more accurately.

How Advanced Tooling Improves EV Production Efficiency

Modern EV manufacturing uses advanced tooling technologies to maintain production quality and efficiency.

A strong EV component tooling partner helps manufacturers by:

- Improving cutting stability

- Reducing vibration during machining

- Increasing production speed

- Improving surface finish quality

This directly impacts production output and customer satisfaction.

Common Problems When Choosing the Wrong Tooling Partner

Selecting suppliers based only on low EV component tooling cost can create multiple production issues:

- Frequent tool breakage

- Surface finish variation

- Higher scrap rate

- Machine downtime

- Inconsistent production quality

Choosing the right EV component tooling partner prevents these problems and helps maintain production stability.

How to Evaluate the Right EV Component Tooling Partner

When selecting a tooling partner, manufacturers should evaluate:

Technical Support

Does the partner provide application guidance and tool optimization support?

Performance Testing Data

Reliable EV component tooling partner companies provide tool performance data and real production case studies.

Supply Chain Reliability

Tool availability is critical for uninterrupted production.

Long-Term EV Component Tooling Cost Stability

Stable pricing helps long-term production planning.

Role of Tooling Innovation in Future EV Manufacturing

The EV industry is evolving quickly with new battery technologies, lightweight vehicle structures, and compact motor designs. These changes demand high precision machining solutions.

A forward-thinking EV component tooling partner continuously invests in research and development. They work on improving coating technology, tool geometry design, and material compatibility.

Innovation in tooling directly helps EV manufacturers achieve faster production cycles and better component quality.

How Tooling Impacts EV Component Surface Quality

Surface quality is extremely critical in EV components, especially in motor shafts, battery enclosures, and transmission components.

A reliable EV component tooling partner ensures stable cutting performance that reduces surface defects and improves dimensional accuracy.

Even if the EV component tooling cost is slightly higher, better surface finish reduces post-processing cost and improves product reliability.

Importance of Process Optimization Support

Tooling suppliers today are not just product suppliers they are process partners.

A strong EV component tooling partner helps manufacturers optimize:

- Cutting parameters

- Tool change intervals

- Tool path strategies

- Production cycle time

This level of support helps manufacturers achieve consistent output quality.

Building Long-Term Tooling Partnerships

Modern EV manufacturers are shifting from supplier-based buying to partnership-based collaboration.

The right EV component tooling partner helps with:

- Process optimization

- Tool innovation

- Cost reduction planning

- Continuous production improvement

This long-term approach improves both production quality and profitability.

Conclusion

Choosing the right EV component tooling partner is a strategic decision that directly impacts manufacturing quality and cost efficiency.

While EV component tooling cost is an important factor, manufacturers must also evaluate performance, reliability, and long-term value.

The right tooling partner helps improve production stability, reduce hidden costs, and maintain high product quality standards. In the fast-growing EV industry, strong tooling partnerships are becoming a key factor for long-term success.