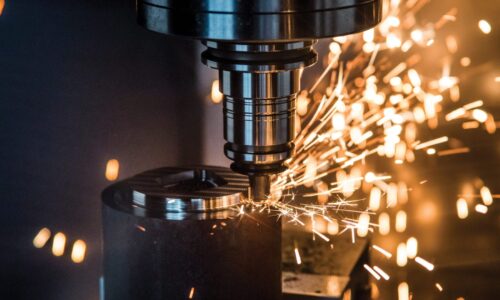

PCD Endmill Supporting Repeatable Quality in Tight-Tolerance Manufacturing

A well-designed PCD end mill becomes a foundation for stability that suddenly facilitates ‘repeatable quality’ towards very high production volumes. Where Precision Becomes a Daily Expectation. If you were to walk into a modern precision manufacturing facility in the early hours of the morning, there is a feeling that borders on discipline in the air, as machines go through their processes in a calculated manner, operators study measurements with equal attention, and every finished piece resembles the one that came before it almost identically. There is little room, if any, for error in the entire process, and every variation in proportion could potentially have consequences in the real world.

This, basically, is what the world of tight tolerance manufacturing is all about. Success is not measured only by how quickly parts can be made, but by how precisely they meet very technical criteria. In this kind of challenging world, cutting tools take on a much deeper role than their primary function of simply removing materials from work pieces. A well-designed PCD end mill becomes a foundation for stability that suddenly facilitates ‘repeatable quality’ towards very high production volumes. And then, working in concert with reliable PCD inserts utilized early in machining sequences, everything suddenly feels ‘controlled,’ ‘predictable,’ and ‘reliable.’

Understanding the True Meaning of Repeatable Quality

Repeatable quality goes beyond making one part perfectly; to make thousands of parts that are exactly alike, without change, error, or correction of any kind.” This level of accuracy is extremely vital to industries such as auto manufacturing, aerospace, electronics, and medicine.

Such consistency is greatly a function of the stability of the cutting process. Over time, small changes from tool wear, vibration, or thermal expansion can cause inconsistencies in the part or process. Such changes may be invisible in the machine operation but can lead to delays or failures in the process over time. A high-performance PCD endmill can greatly help to eliminate such potential risks because they are highly stable in the cutting operation.

Why Tool Stability Matters More Than Speed

Speed often receives the most attention in manufacturing discussions, yet stability is what truly protects quality. A fast process that produces inconsistent parts ultimately slows production through rework and downtime. Tight-tolerance environments demand tools that behave the same way hour after hour.

Because of its extreme hardness and wear resistance, a PCD endmill holds its geometry far longer than traditional carbide tooling. This long-lasting sharpness allows the cutting action to remain smooth and controlled, preventing sudden dimensional change. Supporting operations performed with durable PCD inserts further stabilize the workflow, ensuring that finishing passes begin from a consistent surface condition rather than an unpredictable one.

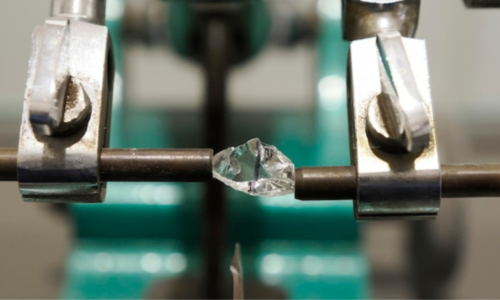

The Material Science Behind a PCD Endmill

The reliability of a PCD endmill comes from polycrystalline diamond, one of the hardest materials used in industrial cutting. Diamond’s natural resistance to abrasion allows the cutting edge to remain sharp even when machining abrasive non-ferrous alloys, composites, and advanced engineering materials.

Beyond hardness, diamond also conducts heat efficiently. Instead of allowing heat to concentrate at the cutting edge, a PCD endmill moves thermal energy away from the tool and workpiece. This reduces the risk of surface damage, dimensional distortion, and premature wear. When earlier machining is handled by thermally stable PCD inserts, the overall temperature balance across the machining cycle improves even further.

Surface Finish as a Reflection of Process Control

In tight-tolerance production, surface finish is not only about appearance. It directly affects sealing ability, friction behavior, coating adhesion, and fatigue strength. Even a slight inconsistency in finish can change how a component performs over time.

A precision-ground PCD endmill creates clean shearing action instead of tearing material, which leads to smoother and more uniform surfaces. Because PCD inserts prepare the workpiece with controlled roughing and semi-finishing, the finishing pass can focus purely on refinement rather than correction. This harmony between tools transforms surface quality from a challenge into a predictable outcome.

Reducing Variation Across Long Production Runs

One of the greatest difficulties in precision manufacturing is maintaining identical quality from the first component to the last. Traditional tools gradually lose sharpness, forcing adjustments that introduce variation between batches.

A PCD endmill dramatically slows this wear process, allowing the same cutting conditions to continue for extended periods. Dimensional accuracy remains stable, inspection frequency decreases, and operators gain confidence in the machining process. Consistent preparation using PCD inserts ensures that every finishing cycle begins under the same conditions, further strengthening repeatability.

Minimizing Vibration and Protecting Dimensional Accuracy

Vibration is a hidden threat in tight-tolerance machining. Even small oscillations can leave microscopic marks or shift dimensions beyond acceptable limits. Because a PCD endmill maintains sharp geometry and balanced cutting forces, it helps reduce the chance of chatter forming during finishing operations.

When rigid and wear-resistant PCD inserts handle earlier material removal, cutting loads remain evenly distributed. This stability carries forward into the finishing stage, protecting dimensional accuracy and preserving the integrity of delicate features.

Lowering the Cost of Precision Through Tool Longevity

Precision manufacturing is often associated with higher production cost, yet advanced tooling can reverse this assumption. Although a PCD endmill represents a higher initial investment, its extended life and consistent performance reduce the need for frequent replacement, machine stoppage, and corrective finishing.

Reliable PCD inserts contribute to this efficiency by maintaining steady roughing performance over time. Together, these tools lower scrap rates, reduce polishing requirements, and improve overall equipment utilization. The result is a process that delivers both accuracy and economic value.

Supporting Automation and Smart Manufacturing Goals

Modern factories increasingly rely on automation, unmanned machining, and real-time monitoring. These systems depend on predictable tool behavior, since unexpected wear or breakage can interrupt entire production cells.

The durability of a PCD endmill makes it well suited for automated environments where long, uninterrupted machining cycles are essential. Stable preparation using PCD inserts ensures that each automated sequence begins with confidence. As smart manufacturing continues to evolve, such reliability becomes a key requirement rather than a luxury.

The Expanding Role of Diamond Tooling in Precision Industries

Industries that once relied solely on carbide are now shifting toward diamond-based solutions. Lightweight alloys, composite structures, and high-performance materials demand cleaner cutting and stronger wear resistance. A modern PCD endmill answers these needs by combining durability with ultra-fine finishing capability.

At the same time, improvements in PCD inserts design allow roughing and semi-finishing to match the same level of precision. This alignment across machining stages creates a fully optimized workflow built for next-generation manufacturing standards.

Building Confidence Through Consistent Results

Perhaps the most valuable benefit of a PCD endmill is not only technical performance but also confidence. When operators trust that each cycle will produce the same accurate result, decision-making becomes faster and production planning becomes simpler.

Support from dependable PCD inserts strengthens this confidence across the entire machining sequence. Instead of reacting to variation, manufacturers can focus on productivity, innovation, and continuous improvement.

Conclusion

Repeatable quality is the true measure of success in tight tolerance manufacture. This calls for more than sophisticated equipment and/or programming. It necessitates cutting tools which will be reliable, consistent, and precise over extended periods.

A PCD endmill, backed by well-engineered PCD inserts, is what is required for consistency in satisfying precision standards in modern machine tools. This helps manufacturers reduce variation, secure surface integrity, and attain reliable dimensional control without constant corrections.

As the world advances further into an era of increasing precision and intelligent manufacturing, the position that a diamond-based technology offers is only growing stronger. For manufacturers that require precision every single day, this technology is not an improvement, but rather the new standard by which precision manufacturing occurs.