- Home

- About

About us

Crafting Quality Precision Tools for Global Excellence

Jain Diamond Tools (JDT) was established in India in 1984 by a group of people having wide industrial experience in precision tool manufacturing. The list of prestigious customers throughout the world is growing because of JDT’s consistency in quality, wide range of products and excellent service to its customers. Also JDT invests in care and quality to meet the high standards of its clients at home and abroad. JDT believes that Quality is the only platform on which an organization can grow. In order to maintain its standard of quality, JDT has its own full fledged, sophisticated manufacturing plant.

The In house Research and Development team of JDT is committed to develop products to meet the customer’s requirements. Our customer service policy not only includes supplying quality dressing tools but also technical support to improve customers tool life and machining process. To conclude in brief, customers faith and satisfaction is our goal. We live in an era of advancing technologies. JDT constantly endeavours to search for the technology necessary to improve the quality of dressing tools and developing the new dressing tools to meet these ever changing needs.

Diamond dressings tools for silicon carbide and aluminum oxide wheels must fulfill the following tasks.

- True the wheels to eliminate run out and correct geometrical shape.

- Restore the required effective roughness of the wheel.

- Keep the wheel open for high efficiency grinding.

Of all the factors involved in grinding process the diamond dressing tool performs a key function in terms of quality and efficiency of the over all process.

Vision

To be a global leader in precision tool manufacturing, renowned for quality, innovation, and customer satisfaction.

Mission

Deliver exceptional quality products, technical support, and innovative solutions. Invest in technology to optimize grinding processes worldwide.

Values

Quality, Customer-Centricity, Innovation, Integrity, Collaboration, Environmental Responsibility, Dedication to Excellence.

What Sets Us Apart?

Exploring Our Unique Attributes

Jain Diamond Tools are extremely confident of its quality diamond dressers. Our confidence on our products is such that we have introduced a JDT Test & Trust program. Under this program we invite consumers to test our quality products in their units, on their own machines and using their own workpieces. All you need to do is to specify your particular requirement and we offer a test sample of the right tool to help you meet your needs and test the tool.

Maximize Tool Longevity

Enhance tool lifespan with strategic maintenance and innovative techniques

- Use the proper sized Diamond.

- Mount the tools rigidly in the tool holder to reduce the vibration.

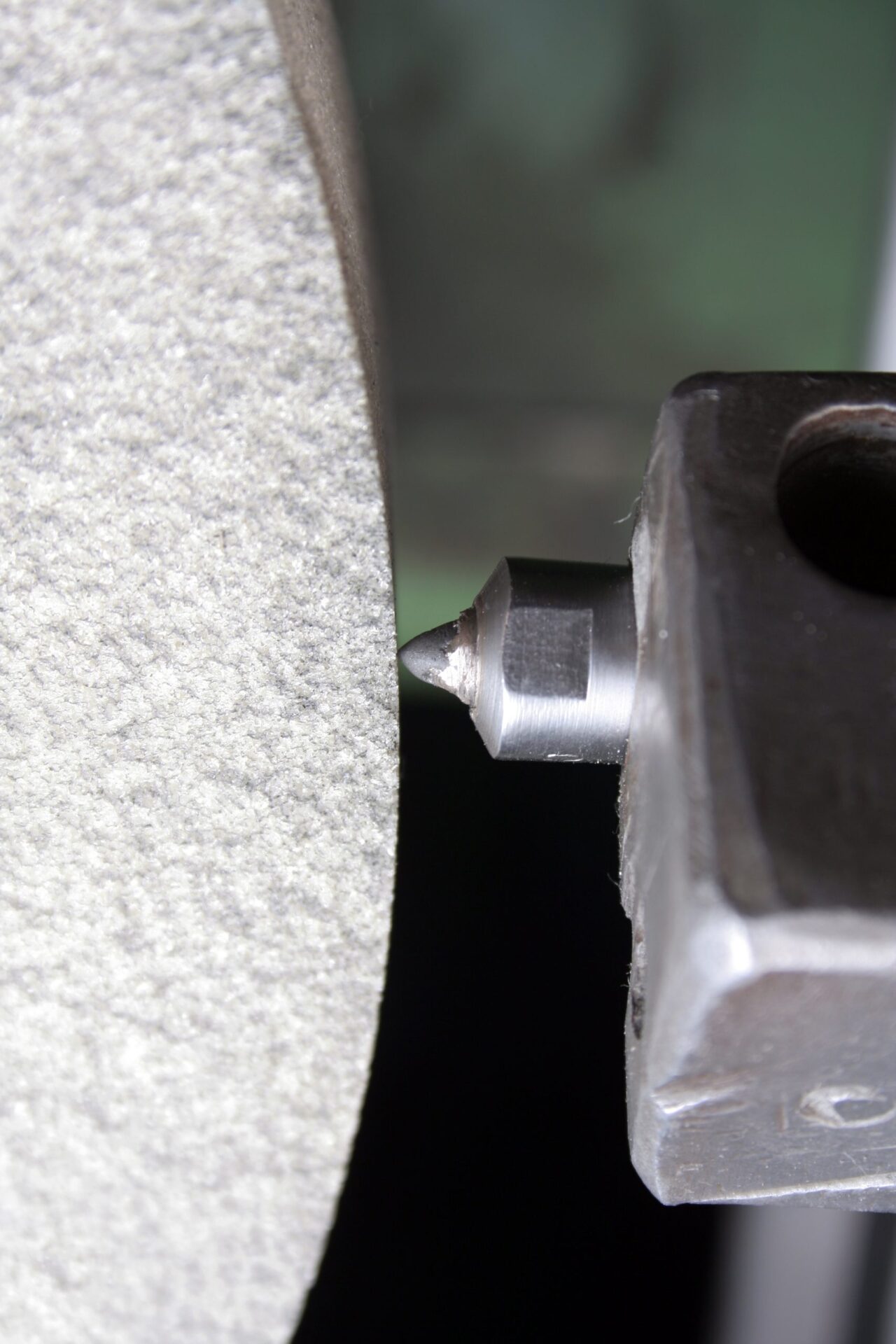

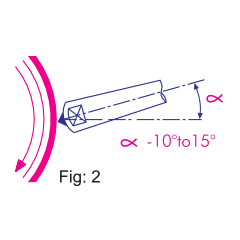

- Select the clamping length ‘a'(Distance from diamond point to Fixture as short as possible to reduce the vibration. (Fig: 1)

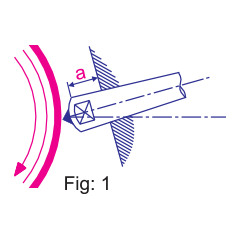

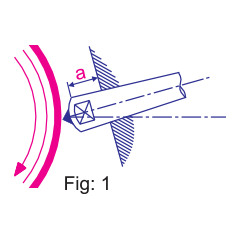

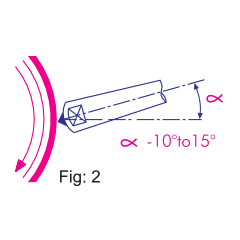

- Incline Tool 10° to 15° to radius of wheel in the direction of wheel rotation to avoid dulling of the Diamond point. (Fig: 2)

- Rotate the Diamond shank frequently by 90° to present new cutting edge. (Fig: 3)

- Always apply plenty of coolant while dressing, because Diamonds are very highly sensitive and can be destroyed by excessive heat generation (Fig: 4)

- For dry dressing do not apply the tool for a long continuous period. Allow the stone to cool naturally before using again. Do not cool the diamond by quenching.

- The depth of cut per dressing pass should not exceed the range of 0.02 to 0.03 mm. (20 to 30 micron).

- If possible, dress the wheel at a speed lower than normal grinding speed.

- Diamond is sensitive to shock and impact. It may be fractured or broken by striking any hard substance such as the bed of a machine or concrete floor. (Fig: 5)

- Protect and store the Diamond tool properly when not in use.

Increase Your Tool Life

- Use the proper sized Diamond.

- Mount the tools rigidly in the tool holder to reduce the vibration.

- Select the clamping length 'a'(Distance from diamond point to Fixture as short as possible to reduce the vibration. (Fig: 1)

- Incline Tool 10° to 15° to radius of wheel in the direction of wheel rotation to avoid dulling of the Diamond point. (Fig: 2)

- Incline Tool 10° to 15° to radius of wheel in the direction of wheel rotation to avoid dulling of the Diamond point. (Fig: 2)

- Rotate the Diamond shank frequently by 90° to present new cutting edge. (Fig: 3)

- Always apply plenty of coolant while dressing, because Diamonds are very highly sensitive and can be destroyed by excessive heat generation (Fig: 4)

- Always apply plenty of coolant while dressing, because Diamonds are very highly sensitive and can be destroyed by excessive heat generation (Fig: 4)

- For dry dressing do not apply the tool for a long continuous period. Allow the stone to cool naturally before using again. Do not cool the diamond by quenching.

- The depth of cut per dressing pass should not exceed the range of 0.02 to 0.03 mm. (20 to 30 micron).

- If possible, dress the wheel at a speed lower than normal grinding speed.

- Diamond is sensitive to shock and impact. It may be fractured or broken by striking any hard substance such as the bed of a machine or concrete floor. (Fig: 5)

- Protect and store the Diamond tool properly when not in use.