Best Diamond Dresser Tool in India: Everything You Need to Know

Hey there! If you’ve ever worked with grinding wheels or precision machining, you know how critical maintaining sharp, accurate wheels is. That’s where the best diamond dresser tool in India comes into play. Whether you’re in a heavy‐machining shop, tool & die, or even manufacturing, the right diamond dresser can make a huge difference in efficiency, finish quality, and cost. Let’s dive into what a diamond dresser is, what to look for, and how these tools are used right here in India.

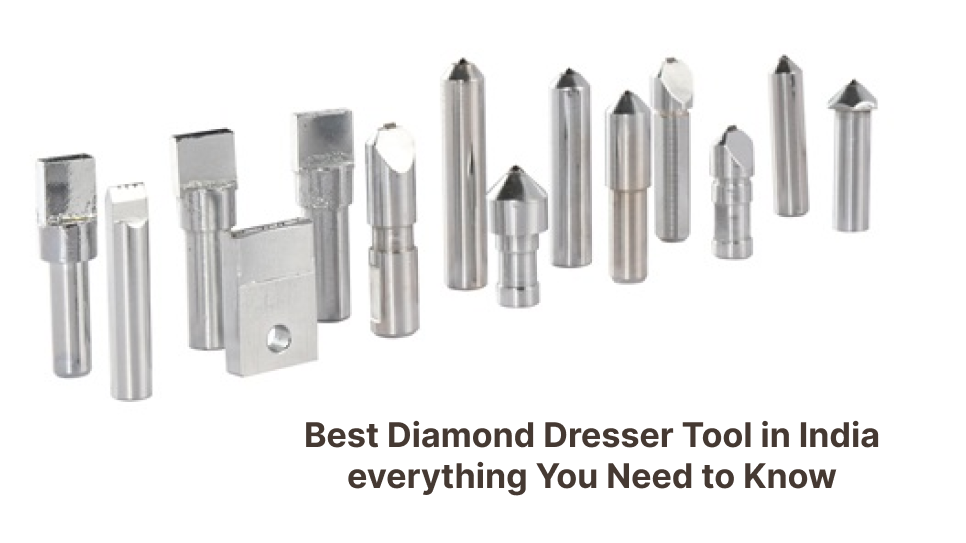

What is a Diamond Dresser?

A diamond dresser is a tool used to true and dress grinding wheels. Over time, wheels get worn, clogged, develop flats or grooves, and lose their profile or shape. The diamond dresser restores the wheel’s shape, sharpness, and clean abrasive surface so that it grinds accurately and efficiently.

There are various types:

- Single Point Diamond Dressers (a single diamond mounted on a shank)

- Multi-Point Diamond Dressers (many small diamonds / points)

- Blade Type Diamond Dressers

- Natural Point Dressers (making use of the natural facets of the diamond)

- Cluster, Crown, or Indexable Dressers etc.

Each type has pros and cons depending on the material of the grinding wheel, required finish, speed of operation, and machine setup.

Why It Matters: The Use of Diamond Dresser in India

In India, many industries rely heavily on grinding operations: automotive components, bearing manufacturing, tools & dies, aerospace, precision engineering, etc. Grinding wheels are often in continuous use, so keeping them in prime condition matters a lot. Here are some reasons why the diamond dresser is important in Indian manufacturing:

- Cost Efficiency: Replacing grinding wheels often is expensive. Dressing extends wheel life.

- Precision & Finish: Customers here demand tight tolerances. A well‐dressed wheel gives better surface finish and accurate geometry.

- Speed & Productivity: A less clogged wheel grinds faster, reduces heat, vibration, rejects.

- Variety of Machines & Conditions: Workshops in India have a wide range of machines—from older conventional grinders to modern CNC units—so flexible and reliable diamond dressers are a must.

- Material Diversity: Indian industries work with many materials: aluminum oxide, silicon carbide, vitrified wheels, resin bonded, etc. The dresser needs to suit the wheel and the workpiece material.

What Makes the Best Diamond Dresser Tool in India

To determine what “best” means in the Indian context, here are the criteria to evaluate:

| Criterion | Why It’s Important |

| Diamond quality (natural vs synthetic / clarity / hardness) | Better diamond → longer life, sharper dressing, less frequent replacement. |

| Type of dresser (single-point, multipoint, blade, natural point, etc.) | Different types for different profiling, precision, and job types. |

| Shank / Body material & design | Rigidity, vibration resistance → accuracy. Indian workshop conditions can be rough, so sturdy is better. |

| Shape / Profile compatibility | If your wheel has a specific profile (radius, convex, concave), the dresser must match. |

| Cut depth, drag angle, feed / traverse speed | These operational parameters affect finish, tool wear, and thermal damage. |

| Cooling / coolant usage | Prevents overheating, preserves diamond integrity. |

| Support, availability, cost | Spares, regrinding, replacement diamonds, delivery are big in India. |

Types of Diamond Dressers & Their Uses in India

Here are a few common types used, with how they are used in Indian shops:

- Single Point Diamond Dresser

- Very popular for truing and dressing tasks where precision is required.

- It has one diamond tip; operators often rotate or index it periodically so a fresh facet is used.

- Ideal for small to medium size wheels or finishing operations.

- Very popular for truing and dressing tasks where precision is required.

- Natural Point Diamond Dresser

- Blade Type Diamond Dressers

- Multi-Point / Cluster Dressers

- Indexable Crown & Crown Type Dressers

How to Use a Diamond Dresser (Practical Tips for Indian Workshops)

Using the tool well is just as important as choosing the right one. Some tips:

- Mounting: Make sure the dresser is rigidly mounted; reduce vibrations. Vibrations damage both the diamond and wheel.

- Drag angle: Always orient the dresser with correct drag angle with respect to wheel rotation (often around 10-15°) so that the diamond cuts, not rips or chips.

- Cut depth / infeed: Take shallow cuts, e.g. 0.001 in (≈ 0.025 mm) per pass. Deeper cuts can fracture the diamond, generate heat.

- Traverse speed: Slow traverse gives a finer finish, faster gives more open wheel structure. Match this with application.

- Coolant: Use coolant whenever possible; keeps temperature down, prevents damage to diamond facet, improves surface finish.

- Maintenance: Rotate or index diamond if possible. If natural point, reset or replace when worn. Clean the tool and wheel to prevent buildup.

Indian Examples & What’s Available

Here are some Indian sources and what they offer, to get a sense of what’s on offer if you want to buy:

- Comet Engineering Company offers a wide range: Indexable crown type, natural point, single point, diamond grit impregnated dressers.

- Solar Diamond Tools (Mumbai / Thane region) has options for stationary dressers, single point, multipoint and blade type dressers, natural & synthetic diamonds.

- Jain Precision Tools in Aurangabad manufactures blade type diamond dressers (needle type, grit type), and also single point & multipoint types.

- DK Tools, Ahmedabad sells multi-point dressers, blade-type, single point ones, with varying shank designs, different angles, etc.

What to Consider Before Buying: Indian Context

In choosing the best diamond dresser tool in India, think about:

- Wheel size / machine type: If you have a big cylindrical grinder vs benchtop surface grinder, the type of dresser needed changes.

- Finish quality required: For rough grinding vs precision finishing.

- Budget vs life-cycle cost: Cheaper diamond dressers cost less now but may wear faster, give poor finish, need more frequent replacement. Better quality might cost more upfront but save money over time.

- Availability of spares / local support: Can you replace diamond points, get regrinding, etc locally?

- Environmental / workshop conditions: Heat, dust, coolant availability—these can affect tool life.

Conclusion

To wrap up, selecting the best diamond dresser tool in India is about matching your dressing needs (profile, precision, wheel type) with a quality tool (good diamonds, proper build) and using it correctly (mounting, infeed, drag angle, coolant, etc.).

If I had to pick a recommendation based on typical Indian workshop needs, it would be:

- For general purpose and precision: a natural point single point diamond dresser with a sturdy steel shank, good diamond quality.

For high volume / large wheels / heavy grinding: a blade type or multipoint dresser, possibly with indexable diamond inserts.