Chip Breaking Inserts Mistakes That Cause Tool Breakage and Downtime

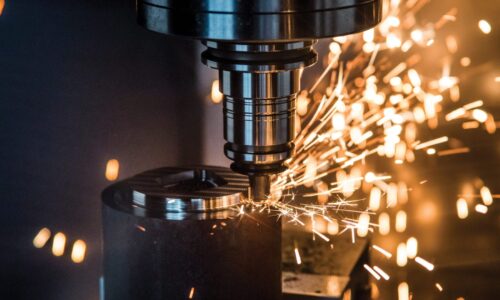

Step into a machining shop at peak productivity, and the atmosphere feels intense yet focused. Machines run continuously, operators watch cutting paths closely, and every second matters. At first, everything seems under control until a machine suddenly stops. A tool has failed. Chips wrap tightly around the part, the surface finish suffers, and production comes to a halt. What began as a normal day quickly turns into stress, delays, and lost time.

In most cases, this does not happen because of a major failure or serious mistake. It often begins quietly with small issues related to chip breaking inserts. When chips are not formed or guided correctly, extra pressure builds on tools and machines. Over time, this leads to tool breakage, unplanned downtime, and higher production costs. Understanding how chip breaking inserts work and how PCBN inserts support modern machining helps prevent these problems before they grow.

Why chip control matters more than it seems

During machining, metal is removed in the form of chips. These chips may look like simple waste material, but they have a direct impact on tool life, surface quality, and machine safety. When chips are short and controlled, they move away easily and allow the cutting process to continue smoothly. When chips become long, sharp, or tangled, they begin to interfere with the cutting edge and the workpiece.

Poor chip control increases friction, traps heat near the cutting zone, and places extra load on the tool. Over time, this leads to damaged cutting edges, unstable machining, and sudden failures. This is exactly why chip breaking inserts are so important. Their role is not just to cut material, but to control how chips behave during cutting so the process remains stable and predictable.

How chip breaking inserts support stable machining

Chip breaking inserts are designed with special grooves, angles, and shapes that guide chips as they form. Instead of allowing chips to grow long and uncontrolled, these features force the chips to curl, fold, and break into smaller pieces. These smaller chips leave the cutting area quickly, reducing heat and friction.

When chip breaking inserts are selected correctly and used within proper cutting conditions, they help maintain steady cutting forces, protect the tool edge, and improve surface finish. Machines run more smoothly, and operators experience fewer interruptions. However, when the wrong insert is used or basic guidelines are ignored, the same inserts can become the source of serious problems.

Mistake one: choosing the wrong chip breaker geometry

One of the most common mistakes in machining is assuming that one insert design can work for every material. In reality, different materials behave very differently during cutting. Softer materials tend to produce long, continuous chips, while harder materials create shorter but more aggressive chips that place heavy stress on the tool.

Using the same chip breaking inserts across multiple materials often results in poor chip formation. For example, an insert geometry designed for steel may struggle badly with cast iron. Similarly, a general-purpose insert may not perform well when machining hardened components.

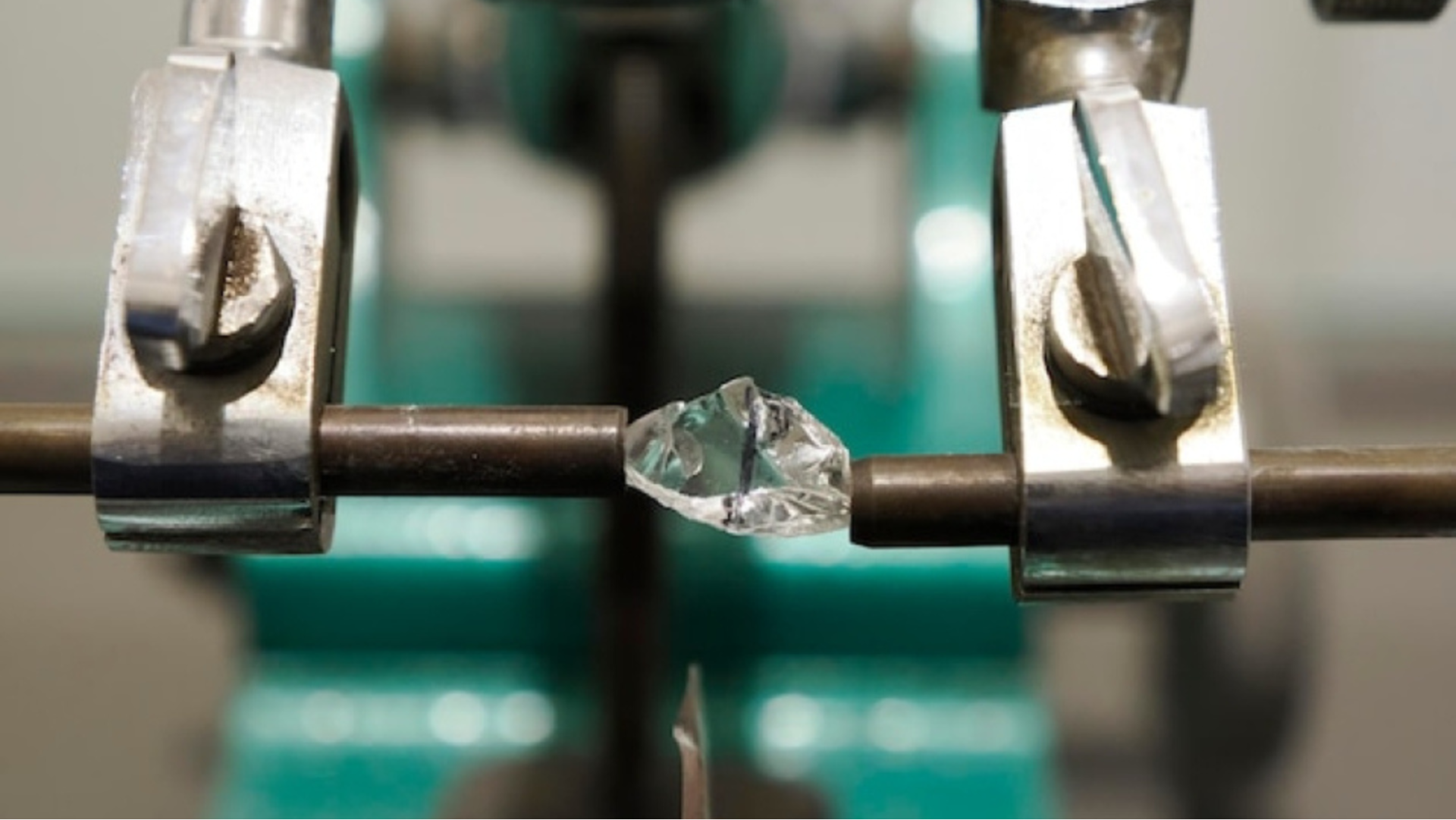

For hard and heat-resistant materials, manufacturers often rely on PCBN inserts. These tools offer excellent strength and thermal stability, but even PCBN inserts require the correct chip-breaking design. Without proper geometry, chip control suffers, and tool life drops quickly.

Mistake two: ignoring cutting parameters

Even the most advanced chip breaking inserts cannot perform properly if cutting parameters are incorrect. Feed rate, cutting speed, and depth of cut all play a role in how chips are formed.

When feed rates are too low, chips may not press firmly against the chip breaker. As a result, long and stringy chips form and wrap around the tool. On the other hand, when feed rates are too high, cutting forces increase sharply, leading to edge chipping or sudden tool breakage.

Many tool failures blamed on insert quality are actually caused by incorrect settings. Chip breaking inserts are designed to work within specific operating ranges, and ignoring these limits often leads to avoidable downtime.

Mistake three: poor chip evacuation

Breaking the chip is only part of the solution. Once formed, the chip must leave the cutting zone quickly. When chips remain near the tool, they rub against the cutting edge and the workpiece, generating heat and vibration.

Poor chip evacuation often occurs when coolant flow is weak, misdirected, or blocked. Overloaded chip conveyors and crowded cutting areas also contribute to this problem. Trapped chips place continuous stress on the tool, and even strong tools like PCBN inserts can fail under these conditions.

Heat buildup and its hidden impact on tools

Heat is one of the biggest threats in machining, yet it is often underestimated. When chip control is poor, chips stay in contact with the tool for longer periods, increasing friction. This trapped heat leads to thermal cracking, edge softening, and reduced coating life.

Chip breaking inserts help manage heat by carrying it away with the chips. When this process fails, tool wear accelerates rapidly. Even PCBN inserts, which are known for handling high temperatures, will suffer when chip flow is unstable.

Tool breakage usually gives warning signs

Tool failure often feels sudden, but warning signs usually appear well before the breakage occurs. Changes in cutting sound, increased vibration, unusual chip color, and inconsistent surface finish are all signals that something is wrong.

In many cases, these signs point back to worn or poorly selected chip breaking inserts. Recognizing these early indicators allows corrective action before a complete failure stops production.

Downtime affects more than production speed

When a tool breaks, the machine stops, but the impact goes far beyond lost machining time. Downtime leads to missed delivery schedules, additional labor costs, machine checks, and scrap or rework.

Repeated downtime reduces confidence in the process. Operators may slow down machines to avoid failure, which lowers overall productivity. Addressing chip control issues early with the right chip breaking inserts helps prevent this chain reaction.

The growing role of PCBN inserts in modern machining

As industries demand tighter tolerances and harder materials, PCBN inserts have become essential in many applications, especially in automotive and aerospace manufacturing. Their hardness and thermal stability allow them to perform where traditional tools struggle.

However, PCBN inserts are not immune to poor chip control. Without proper chip-breaking features, they face the same risks of heat buildup and tool failure. Matching PCBN inserts with effective chip control is critical for consistent performance.

Delaying insert replacement increases risk

Worn chip breaking inserts lose their ability to guide chips correctly. Their grooves become smooth, and chips start flowing unpredictably. Many manufacturers delay replacement to save costs, but this often leads to greater losses.

As inserts wear, cutting forces increase, chip control worsens, and the chance of sudden breakage rises. Replacing chip breaking inserts at the right time is far more cost-effective than dealing with unplanned downtime.

Operator habits influence chip control

Even with the right tools, operator behavior matters. Overriding recommended parameters, clearing chips manually during cutting, or ignoring warning signs increases risk.

When operators understand how chip breaking inserts work and what healthy chips look like, they can respond early and prevent failures. Simple awareness can significantly improve tool life and process stability.

Confidence grows with stable chip control

When chip control is consistent, machining feels smoother. Machines run quietly, tools last longer, and surface quality remains steady. Operators trust the process and can focus on productivity rather than damage control.

Reliable chip breaking inserts, supported by correct use of PCBN inserts, restore this confidence and allow machining operations to run at their full potential.

Small changes that deliver big results

Improving chip control does not always require expensive upgrades. Reviewing insert selection, adjusting cutting parameters, improving coolant direction, and monitoring wear can dramatically reduce tool breakage and downtime.

These small improvements create a more stable, predictable machining environment.

Conclusion

Tool breakage and downtime rarely come from a single major mistake. They build slowly through small, repeated issues many of which begin with poor chip control.

Chip breaking inserts play a critical role in maintaining stable, safe, and efficient machining. When used incorrectly, they quietly create the conditions for failure. When selected and applied properly, they protect tools, machines, and production schedules.

As machining continues to advance, PCBN inserts will play an even bigger role. But their success still depends on effective chip control. In the end, good machining is not just about cutting metal it is about controlling every detail of the process, starting with the chips.