What to Look for When Buying Diamond CBN Wheels

- By akshada

- Posted on

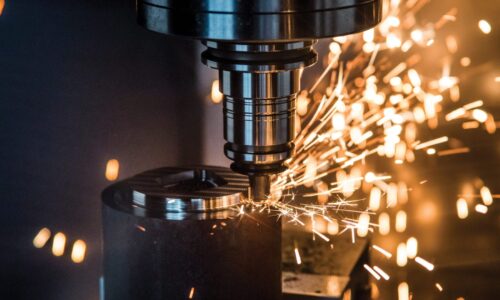

Diamond CBN wheels are Cubic Boron Nitride. These are the most efficient solutions for grinding in industrial applications, possessing high hardness and stable operation at elevated temperatures. CBN wheels are ideal for grinding hard materials such as steel alloys, high-speed steels, and other ferrous metals. They provide better performance compared with conventional grinding wheels. Thus, manufacturers who make precise, high-quality finishes always need these wheels.

When purchasing Diamond CBN Wheels, you will have to understand what will drive performance and durability. In most cases, a wrongly chosen wheel leads to less than efficient grinding, uneven wear, and even breakage of the workpiece. As one of the leaders in diamond tool production, Jain Diamond Tools designs superior-quality CBN wheels, conforming to industrial norms. You will be taken through some critical points you need to consider in purchasing Diamond CBN Wheels. In doing this, you should make an informed, value-driven decision.

Introduction to CBN Wheels

CBN wheels are of cubic boron nitride. This is the second hardest material known after diamond. For this reason, CBN is very well-suited for grinding ferrous metals. In fact, it is very inconvenient to machine these in many cases. CBN wheels, unlike their diamond counterpart, are designed to grind hard metals like tool steels, high-speed steels, and superalloys.

Jain Diamond Tools is one of the leading manufacturers of diamond tools, including a complete variety of Diamond CBN Wheels for diverse industrial applications in manufacturing, aerospace, automotive, and medical device manufacturing. Jain Diamond Tools has gained a reputation for long-wearing and high-performance wheels.

1. Identify the Application and Material Type

Determine your application for Diamond CBN Wheels, first of all. Wheels are designed based on the material to be machined. CBN wheels are the best choice for grinding very hard metals, such as steel or high-speed alloys. Key applications of Diamond CBN Wheels are:

- Tool Grinding: CBN wheels are ideal for sharpening and shaping cutting tools in machining. Such tools include drills, milling cutters, and grinding tools.

- Precision Grinding: For high tolerance applications such as aerospace or automotive, CBN wheels deliver precision.

- Surface Grinding: Fine-grit CBN wheels can help you achieve a smooth surface finish.

- Hard Material Grinding Use CBN wheels are applied to grind such hard materials as stainless steel, cast iron, and carbide.

However, in order to acquire the correct CBN wheel, it is necessary to define the hardness of the material to be ground. For example, a market leader, Jain Diamond Tools, has a variety of CBN wheels for various jobs so that the customer may receive the correct tool for his grinding application.

2. Grit Size and Structure

The grit size of the grinding wheel further determines how aggressively it will cut and how clean the finish is going to be. Grit size refers to the size of the abrasive particles in the wheel. Smaller grits provide a finer finish, while larger grits give better material removal.

- Coarse Grit: The coarse-grit wheels are best suited to the operation of coarse grinding and fast material removal. They are normally used in cutting and pre-grinding operations where high material removal rates are required.

- Fine Grit: Fine-grit wheels are ideal for the production of a smooth surface finish. It is normally used in precision grinding operations where accuracy is required.

When purchasing the Diamond CBN Wheels, you should evaluate the grit size that you will use to accomplish your grinding task. The best manufacturer of CBN wheels is Jain Diamond Tools, and they have a wide range of grit sizes so you are going to find one that fits your requirements perfectly.

3. Bond Type

The bond type in a CBN wheel accounts for its application and effectiveness. A bond is the material holding abrasive grains together. The three common bonds used in Diamond CBN wheels are:

- Resin Bond: This is one of the most versatile and widely used bond types. Resin bonded wheels are impressively balanced with sharpness and wear resistance and can be used in grinding a variety of jobs. They are also quite flexible, usually for general-purpose grinding.

- Metal Bond: The metal bond wheel has great durability and strength. These wheels are ideal for operation under grinding forces and can be used where large amounts of work are to be done and used for hard material. They are not sharp like the resin bonds.

- Vitrified Bond: These bonds are highly stable and provide excellent retention of form when grinding. Vitrified bond wheels are for high-precision tasks, and they are best used when constant performance is very important.

The type of bond to be used largely depends on the type of grinding operation you require for your work. If you want a versatile product, Jain Diamond Tools has resin bond and metal bond CBN wheels in various sizes so that you get an appropriate one according to your requirement.

4. Wheel Shape and Size

The CBN Wheel is necessary for compatibility with your grinding machine and to achieve the result you would expect when grinding. Different applications for grinding tasks require different shapes of wheels. Among them, the most common shapes of CBN wheels are as follows:

- Flat Wheels: These are most commonly used wheels in surface grinding and also in other flat-surface applications.

- Cup Wheels: It is used when one is performing an internal grinding operation or when the structure of the wheel is more complicated.

- Cylindrical Wheels These are more suitable for cylindrical grinding and find use in most precision applications.

The size of the wheels determines their effectiveness. Large wheels are also generally found in high volume production environments. Small wheels have a number of applications in precision and specialty work. Make sure to select a CBN wheel that matches your grinding machine specifications.

5. Durability and Wear Resistance

Indeed, durability is one of the foremost factors to be considered when checking on Diamond CBN Wheels. Topnotch wheels from producers like Jain Diamond Tools also can stand exceptional wear resistance, which means they last longer and stay more efficient longer in grinding.

The lifetime of a wheel is determined by the type of bond, grit size, or quality of the abrasive material used. Jain Diamond Tools‘ CBN wheels are made for the tasks that relate to rigorous grinding work and high performance even during long-lasting use.

6. Thermal Stability and Heat Resistance

Grinding results in large quantities of heat during the process; it may damage the wheel and even the workpiece. Thus, a high-quality diamond CBN wheel should be one which resists significant temperatures before degrading. It has been proven that CBN has thermal stability at the top and is, due to this reason, used to make ideal wheels for grinding high-speed or heavy-duty operations.

Since Jain Diamond Tools ensure high heat resistance for CBN wheels, there is less possibility of thermal damage to the wheel and workpiece. Therefore, this tool is very suitable for high-temperature grinding applications such as the aerospace or automobile manufacturing industries.

7. Cost vs. Performance

One consideration is the price when Diamond CBN Wheels are purchased, but the product’s main determinant is far from price. While the cheap ones will look cheaper, they wear out quicker, and the grinding performance drops significantly. Which means you’ll have to replace more often and incur more expensive maintenance jobs. Quality CBN wheels will outperform most; they will last longer; in the long run, you will save your money on these frequent replacements and maintenance jobs.

Jain Diamond Tools sell CBN wheels at the right price with the value for your money. Jain Diamond Tools will offer a perfect blend of performance and affordability that will ensure you get a high return from their wheels.

8. Safety Standards and Compliance

Safety standards and compliance are also one key aspect when purchasing Diamond CBN Wheels. Jain Diamond Tools manufactures wheels according to international safety norms, and the accident risk during operations is reduced to a minimum degree. Apart from this, their wheels undergo very tough quality checks so that performance under different conditions is provided without any hassle.

9. After-Sales Support and Customer Service

This has ensured that while buying a Diamond CBN Wheel one must have a good support system post sales. All kinds of customer support and the complete services at Jain Diamond Tools will help their users solve any problem related to the product. An educating, dedicated team will be provided to you; with their help, the potential for your CBN wheels can be maximised.

Conclusion

The correct Diamond CBN Wheel, therefore, will ensure that your grinding process works under the best possible conditions. This goes hand-in-hand with size of grit and type of bonding, besides durability and thermal stability, being compatible with the grinding machine. A superior CBN wheel ensures superior results, and Jain Diamond Tools are a leading diamond tool manufacturer known for high-quality Diamond CBN Wheels to match demanding industrial applications. Whether you need precision grinding, tool sharpening, or high-volume production, Jain Diamond Tools has your answer with the right solution.

Using CBN wheels from Jain Diamond Tools, you can come out with increased efficiency, longer life of your tools, and consistent grinding performance, making them the perfect fit for your business.

FAQs:

Q- 1. What is the main advantage of using Diamond CBN Wheels?

Ans- Diamond and CBN Wheels are much stouter and provide finer accuracy for grinding hard metal alloys and steel. They also resist heat and abrasion and are suitable for high-performance requirements.

Q-2. How do I choose the right grit size for my application?

Ans- Diamond and CBN Wheels are much stouter and provide finer accuracy for grinding hard metal alloys and steel. They also resist heat and abrasion and are suitable for high-performance requirements.

Q-3. Can CBN wheels be used for grinding non-ferrous materials?

Ans- Though CBN wheels are used mostly on ferrous metals, they may be used on some non-ferrous materials if the need arises, but diamond wheels are normally used for non-ferrous applications.

Q-4. How can I maintain my Diamond CBN Wheels?

Ans- Regular cleaning, wheel dressing, and proper machine alignment will ensure high performance and extra life with your Diamond CBN Wheels.

Q-5. Are Diamond CBN Wheels compatible with all grinding machines?

Ans- Yes, but they must be the size, shape, and type that matches your machine for the best results.