Manufacturer and Supplier of Diamond Wheels & Diamond Tools in India

In manufacturing environment, precision isn’t optional it’s expected. Whether you’re producing automotive components, precision bearings, carbide tools, or aerospace parts, one thing remains constant: your tooling partner directly impacts your output quality. That’s why choosing the right Manufacturer and Supplier is not just a purchasing decision, but a strategic one.

Every manufacturer faces similar questions.

Will the tools last longer?

Will the surface finish stay consistent?

Will production downtime reduce or increase?

The answers depend heavily on working with a reliable Manufacturer and Supplier who understands machining challenges, material behavior, and real-world production demands. Especially when it comes to advanced solutions like diamond tools, experience and consistency matter more than ever.

Why the Right Manufacturer and Supplier Matters

Precision tooling works behind the scenes, but its impact is visible everywhere cycle time, finish quality, tool life, and cost per component. A dependable Manufacturer and Supplier doesn’t simply deliver tools; they deliver performance reliability.

In Indian manufacturing, where production volumes are rising and tolerances are tightening, tooling inconsistency can lead to rework, scrap, and unexpected downtime. Partnering with the right Manufacturer and Supplier ensures stable quality, predictable results, and long-term cost efficiency.

What separates an average supplier from a trusted partner is application knowledge. A knowledgeable Manufacturer and Supplier understands which tool geometry works best, how heat affects performance, and how tooling can be optimized for specific materials.

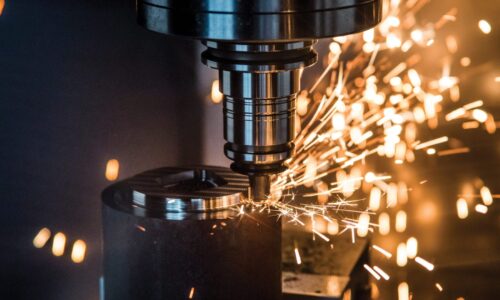

The Role of Diamond Tools in Modern Manufacturing

Diamond tools have become essential for industries that demand high accuracy, superior surface finish, and long tool life. From grinding and dressing to precision cutting, diamond-based solutions are engineered to handle extreme conditions with stability.

As a specialized Manufacturer and Supplier, the focus is on delivering tools that maintain sharpness, resist wear, and perform consistently even under high-speed or high-temperature operations. This becomes particularly important in applications involving hardened steels, carbides, ceramics, and advanced alloys.

High-quality Diamond Wheels play a critical role in grinding operations where dimensional accuracy and surface integrity are non-negotiable. When sourced from an experienced Manufacturer and Supplier, these tools help reduce vibration, improve finish quality, and extend dressing intervals.

What to Expect from a Reliable Manufacturer and Supplier

Not all tooling partners offer the same level of support. A professional Manufacturer and Supplier stands out by offering more than just a catalog of products.

Key expectations include:

- Consistent quality standards across batches

- Application-specific tool recommendations

- Technical guidance before and after purchase

- Reliable delivery timelines

- Custom solutions for specialized requirements

A trusted Manufacturer and Supplier works closely with customers to understand machining conditions and recommend tools that align with productivity goals rather than pushing generic solutions.

Diamond Wheels and Grinding Performance

Grinding operations demand extreme accuracy, and this is where Diamond Wheels prove their value. Designed for precision material removal, they help achieve superior finishes while maintaining dimensional control.

When manufactured correctly, Diamond Wheels offer longer service life, reduced dressing frequency, and stable grinding behavior. A skilled Manufacturer and Supplier ensures proper bonding, diamond concentration, and wheel balance to meet application-specific needs.

For manufacturers looking to optimize grinding efficiency, sourcing Diamond Wheels from a proven partner can significantly improve consistency across production cycles.

Customization: A Key Advantage

Standard tools work for standard applications but modern manufacturing is rarely standard. A capable Manufacturer and Supplier offers customization to match unique machining challenges.

Customized diamond tools may include:

- Application-specific profiles

- Optimized grit sizes

- Special bond formulations

- Tools designed for specific machines or materials

This customization approach allows manufacturers to achieve better tool life, reduced cycle times, and improved finish quality benefits that directly impact profitability.

Industries Served Across India

An experienced Manufacturer and Supplier supports a wide range of industries, including:

- Automotive and auto components

- Aerospace and defense

- Bearing manufacturing

- Carbide and cutting tool production

- Precision engineering units

Each industry has distinct tooling requirements, and working with a knowledgeable Manufacturer and Supplier ensures that tools are matched accurately to operational demands.

Why Indian Manufacturers Prefer Local Expertise

Choosing an India-based Manufacturer and Supplier offers advantages beyond pricing. Local manufacturing expertise means faster support, better communication, and tooling solutions adapted to Indian production environments.

A domestic Manufacturer and Supplier understands machine conditions, production volumes, and cost sensitivities common in Indian industries. This leads to practical, performance-driven solutions rather than one-size-fits-all products.

Long-Term Value Over Short-Term Cost

While low-cost tools may seem attractive initially, inconsistent performance often leads to higher overall costs. A reliable Manufacturer and Supplier focuses on long-term value tools that last longer, perform consistently, and reduce downtime.

Over time, this approach lowers tooling consumption, improves part quality, and stabilizes production output. That’s why experienced manufacturers prioritize partnership over price alone.

Choosing the Right Partner for Your Growth

The right Manufacturer and Supplier grows with your business. As production scales and requirements evolve, your tooling partner should be able to adapt, innovate, and support new challenges.

Whether you’re upgrading machining capability, improving finish quality, or reducing rejection rates, working with an experienced partner makes a measurable difference.

Ready to Upgrade Your Tooling Performance?

If you’re looking for a dependable Manufacturer and Supplier of diamond tools in India who understands precision, performance, and production realities, the next step is simply start a conversation.

Discuss your application, share your challenges, and explore tooling solutions designed to deliver consistent results. The right tools don’t just cut or grind, they help your business move forward with confidence.