PCBN Special tool Every Glass Manufacturer Should Be Using Today

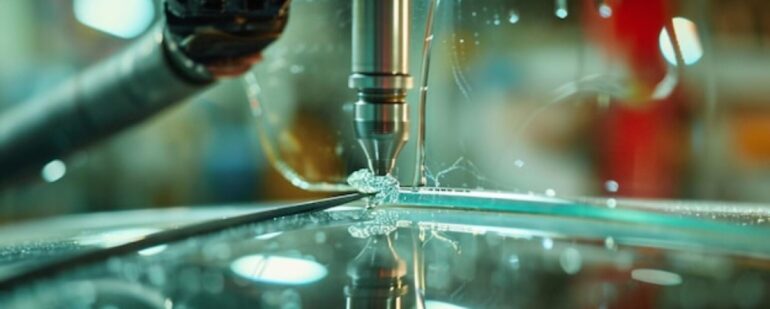

If you’re in the glass industry, you already know one thing for sure: glass machining leaves no room for error. One wrong cut, one chipped edge, or one overheated tool can turn a perfect glass sheet into costly scrap. Many glass manufacturers struggle daily with breakage, poor surface finish, slow machining speed, and rising tooling costs. This is exactly where the PCBN Special tool,PCD Endmill becomes a game-changer.

Today, more glass manufacturers are shifting toward advanced cutting solutions because traditional tools simply cannot keep up with modern glass processing demands. In this blog, we’ll break down why the PCD Endmill is essential, how it solves common glass machining problems, and how it works alongside advanced solutions like PCBN Special tool and PCBN inserts to improve overall productivity.

Why Glass Machining Is So Challenging

Glass is hard, brittle, and extremely sensitive to heat and vibration. Unlike metals, it doesn’t deform cracks, chips, or shatters. Many manufacturers still rely on conventional carbide tools, expecting better results with higher speeds or more coolant. Unfortunately, this often leads to:

- Edge chipping and micro-cracks

- Excessive tool wear

- Poor surface finish

- Frequent tool changes

- High rejection and rework rates

These issues not only slow production but also directly impact profit margins.

This is where a PCD Endmill makes a noticeable difference.

What Makes a PCBN Special tool Ideal for Glass

A PCBN Special tool is manufactured using Polycrystalline Diamond, one of the hardest cutting materials available. This makes it especially suitable for machining non-ferrous, abrasive, and brittle materials like glass.

Unlike standard tools, a PCD Endmill offers:

- Exceptional hardness and wear resistance

- Minimal friction during cutting

- Superior heat dissipation

- Longer tool life

- Cleaner and smoother edges

For glass manufacturers, this means consistent quality and stable production.

How a PCBN Special tool Improves Glass Cutting Quality

One of the biggest advantages of using a PCBN Special tool and PCD Endmill is the dramatic improvement in cutting quality. The sharp diamond cutting edges reduce vibration and eliminate uneven cutting pressure. As a result:

- Edge chipping is minimized

- Surface finish improves significantly

- Dimensional accuracy remains consistent

- Post-processing work is reduced

Glass manufacturers who switch to a PCBN Special tool, often notice fewer rejects within the first few production cycles.

Faster Production Without Compromising Safety

Speed matters in modern glass manufacturing, but higher speeds with the wrong tool can increase breakage risks. A PCBN Special tool allows higher cutting speeds without stressing the glass.

Because of its low coefficient of friction and high thermal stability, the PCD Endmill maintains stable cutting even during long production runs. This results in:

- Faster cycle times

- Stable machining performance

- Reduced downtime due to tool failure

When paired correctly with advanced solutions like a PCD Endmill, manufacturers can achieve even better control over precision operations in hybrid machining environments.

Tool Life That Reduces Overall Cost

At first glance, a PCBN Special tool may seem more expensive than conventional tools. However, when you look at the bigger picture, it significantly reduces overall costs.

A single PCBN Special tool can last multiple times longer than carbide tools. This means:

- Fewer tool replacements

- Lower machine stoppages

- Reduced inventory costs

- Consistent output quality

In facilities where glass machining is combined with harder materials, manufacturers often complement the PCBN Special tool with PCBN inserts to handle different cutting applications efficiently.

Reduced Heat and Stress on Glass Material

Heat is one of the biggest enemies of glass machining. Excessive heat leads to thermal cracks and sudden breakage. The PCD Endmill generates far less heat during cutting due to its diamond structure.

This controlled cutting action ensures:

- Minimal thermal damage

- Lower internal stress in glass

- Better edge integrity

- Safer machining operations

For complex production lines, combining a PCD Endmill with a PCBN Special tool helps maintain balance between delicate glass cutting and harder machining requirements.

Consistency That Builds Customer Trust

In the glass industry, consistency is everything. Customers expect uniform quality across every batch. A PCD Endmill delivers repeatable results because it maintains its cutting geometry for a long time.

With consistent performance:

- Quality remains uniform

- Rework and inspection time decreases

- Customer complaints reduce

- Brand reputation improves

Many manufacturers using PCBN inserts for secondary operations find that integrating a PCD Endmill for glass-specific cutting creates a more reliable and predictable workflow.

Ideal Applications of PCBN Special tool in Glass Industry

A PCBN Special tool is widely used across various glass applications, including:

- Architectural glass processing

- Automotive glass components

- Display and optical glass

- Industrial and technical glass parts

In multi-material production environments, manufacturers often rely on PCD Endmill solutions alongside the PCD Endmill to maintain flexibility and efficiency.

Common Mistakes Glass Manufacturers Make Without a PCBN Special tool

Many manufacturers delay upgrading their tooling and face recurring problems such as:

- Rising rejection rates

- Inconsistent cutting quality

- Frequent tool breakage

- High maintenance costs

These issues often disappear once a PCD Endmill is introduced into the process. When supported with properly selected PCBN inserts, the entire machining setup becomes more stable and cost-effective.

How to Get the Best Results from a PCD Endmill

To maximize the performance of a PCD Endmill, manufacturers should:

- Use stable machine setups

- Optimize cutting parameters

- Maintain proper coolant flow

- Match tools with the right material application

When glass machining is part of a broader production line, integrating a PCBN Special tool for hard-turning or finishing operations ensures complete machining efficiency.

Why Smart Glass Manufacturers Are Switching Now

The glass industry is becoming more competitive, and margins are getting tighter. Manufacturers who continue using outdated tools struggle to keep up with quality expectations and delivery timelines.

A PCD Endmill offers a future-ready solution by:

- Improving productivity

- Reducing scrap

- Enhancing surface quality

- Lowering long-term tooling costs

When combined with PCBN inserts and other advanced tooling solutions, it creates a powerful machining ecosystem that supports growth and scalability.

Conclusion

For glass manufacturers aiming to improve quality, reduce waste, and stay competitive, upgrading to a PCD Endmill is no longer optional, it’s essential. Its ability to deliver clean cuts, long tool life, and stable performance makes it the most reliable choice for modern glass machining.

If your production involves multiple materials or high-precision requirements, pairing the PCD Endmill with a PCBN Special tool and high-quality PCBN inserts can unlock even greater efficiency.

The question is no longer whether you should adopt a PCBN Special tool, PCD Endmill, but how soon you want to see the results in your glass manufacturing process.

Now is the right time to upgrade your tooling and cut glass with confidence.