How a PCD Grewing Tool Can Transform Your Cutting Performance

Have you ever had a machining setup that looked perfect on paper ideal RPM, precise toolpath, stable fixturing yet the final groove still came out inconsistent, rough, or completely out of tolerance? It’s one of the most frustrating experiences for manufacturers. When accuracy drops, costs rise, deadlines stretch, and clients get disappointed. In many of these cases, the root cause isn’t the machine, the operator, or even the material, it’s the tool. And this is exactly where a PCD grewing tool steps in as a game-changing upgrade for anyone demanding flawless grooving performance.

In this detailed guide, we’ll break down how a PCD grewing tool enhances machining output, why industries rely on it for grooving operations, and how pairing it with the right Special PCD tool setup can elevate overall machining efficiency.

1. What Is a PCD Grewing Tool and Why Does It Matter?

A PCD grewing tool is a precision-engineered cutting tool made using Polycrystalline Diamond (PCD), a material known for its extreme hardness and wear resistance. These tools are specifically designed for high-accuracy grooving applications where dimensional consistency, surface quality, and repeatability are essential.

PCD is created under high-pressure, high-temperature conditions, forming a diamond matrix that offers exceptional cutting performance, especially on:

- Non-ferrous metals

- Aluminum alloys

- Copper and brass

- Carbon composites

- Graphite

- Advanced polymers

- Abrasive materials

Where traditional carbide tools wear out quickly, a PCD grewing tool continues performing with predictable stability, making it ideal for high-volume or high-precision machining environments.

2. The Cutting Performance Challenges Most Manufacturers Face

Even the most advanced machines can struggle when the tooling is not optimized. Businesses commonly face issues like:

- Rapid tool wear

- Inconsistent groove dimensions

- Poor surface finish

- Vibration and chatter

- Frequent downtime for tool changes

- High machining costs per component

These problems become more severe when working with abrasive materials or when production demands are high. A PCD grewing tool directly addresses these issues by offering unbeatable hardness, durability, and thermal stability during cutting operations. When paired with a Special PCD tool for custom applications, manufacturers gain even more precision and efficiency.

3. Key Advantages of Using a PCD Grewing Tool

Here’s how a PCD grewing tool transforms your machining performance:

1. Exceptional Tool Life

PCD is one of the hardest materials on earth. This gives the PCD grewing tool incredible longevity compared to carbide or HSS tools. Manufacturers often experience 10–50X longer tool life, drastically lowering replacement frequency and improving productivity.

2. Consistent and Accurate Groove Dimensions

Accuracy is crucial in grooving, especially for components used in automotive powertrains, aerospace engine parts, and electronic housings. A PCD grewing tool maintains dimensional stability even during long production cycles, preventing variation and improving part quality.

3. Superior Surface Finish

PCD’s sharpness and stability help eliminate burr formation and reduce surface roughness. This minimizes or eliminates post-processing steps like polishing or deburring.

4. High-Speed Machining Capability

With its excellent thermal conductivity, a PCD grewing tool supports high cutting speeds without losing edge integrity. This results in faster cycle times and increased production output.

5. Ideal for Abrasive Materials

Where carbide tools fail quickly, a PCD grewing tool thrives. From composites to graphite and aluminum alloys, the tool maintains its cutting edge longer and resists abrasion far more effectively.

6. Lower Overall Machining Cost

Though initial cost is higher, the longer tool life, reduced downtime, and improved consistency provide a significantly better cost-per-part ratio. When integrated with other Special PCD tool solutions, the savings grow even more.

Why Industries Are Moving Toward PCD Grewing Tool Solutions

Today’s industries cannot afford performance inconsistency or machine downtime. This shift has led manufacturing leaders to adopt advanced PCD tooling for greater reliability. Let’s explore why different sectors rely on the PCD grewing tool:

Automotive

Precision grooving is essential in engine parts, fuel systems, brake assemblies, transmission components, and EV battery structures. A PCD grewing tool ensures tight tolerances and consistent performance across mass production cycles.

Aerospace

Lightweight materials such as titanium composites and aluminum alloys dominate aerospace design. The PCD grewing tool handles these materials effortlessly, delivering accuracy without rapid wear.

Electronics & Semiconductors

Micro-grooves and delicate features require ultra-precise machining. Both PCD grewing tool and Special PCD tool configurations play a crucial role in preventing material damage.

General Precision Engineering

For complex grooving and slotting operations, the stability of a PCD grewing tool improves throughput and reduces rejection rates.

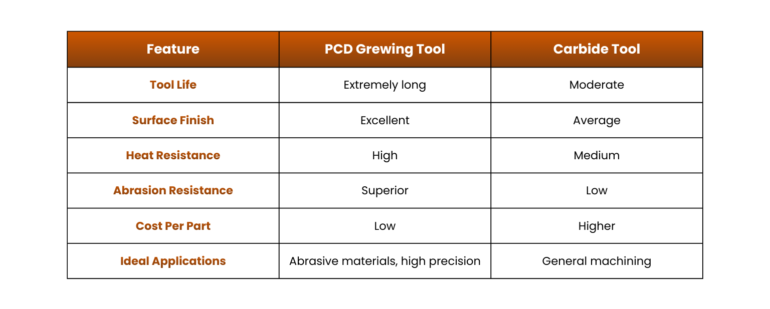

5. PCD Grewing Tool vs. Conventional Cutting Tools

This comparison highlights the performance leap achieved when switching to a PCD grewing tool, especially when paired with application-specific Special PCD tool designs.

6. How Special PCD Tool and PCD Grewing Tool Work Together

A PCD grewing tool handles precision grooving, but machining needs often extend beyond standard operations. For custom requirements—complex profiles, tight tolerances, multi-step machining—industries depend on Special PCD tools.

Together, these tools deliver:

- Tailored cutting geometry

- Application-specific performance

- Higher machining flexibility

- Improved consistency

- Reduced cycle time

Using both a PCD grewing tool and a Special PCD tool optimizes entire manufacturing lines, making production smoother and more efficient.

7. When Should You Upgrade to a PCD Grewing Tool?

You should consider upgrading to a PCD grewing tool if you experience:

- Excessive tool breakage

- Inconsistent groove depths or widths

- High scrappage rates

- Poor surface finish

- Long cycle times

- Tooling costs increasing month by month

- Machining of abrasive or non-ferrous materials

Manufacturers often see immediate performance improvement after switching to PCD tools, especially when integrating Special PCD tool setups for specialized components.

8. Tips for Getting the Best Performance Out of Your PCD Grewing Tool

To maximize the value of your PCD grewing tool, keep these best practices in mind:

- Maintain rigid fixturing to prevent vibration

- Use recommended feed and speed values

- Keep tool holders clean and stable

- Monitor coolant flow for consistent temperature control

- Regularly inspect cutting edges under magnification

- Pair with a compatible Special PCD tool for multi-step machining

Following these guidelines ensures long-lasting performance and repeatable output.

Conclusion: The PCD Grewing Tool Is a Game-Changer for Modern Machining

In the world of precision manufacturing, every micron counts. A PCD grewing tool gives manufacturers the edge by offering superior tool life, exceptional accuracy, and outstanding surface finish quality. Its durability, capability to handle abrasive materials, and suitability for high-speed machining make it an essential choice for industries striving to meet modern manufacturing standards.

When combined with the versatility and customization of a Special PCD tool, businesses gain a full-spectrum tooling solution capable of transforming their machining performance, reducing production costs, and delivering consistent quality cycle after cycle.

If your goal is to upgrade precision, boost productivity, and ensure flawless grooving results, a PCD grewing tool is not just an option it’s the right investment for long-term success.