Stopping Automotive Rework Starts with the Right PCD Grewing Tool Supplier

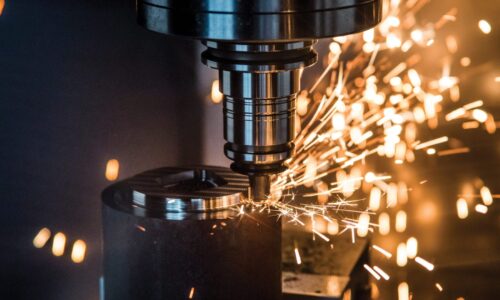

PCD grewing tool supplier selection is something many automotive manufacturers don’t think about until production problems start showing up. Walk through any busy automotive factory floor and you’ll notice how everything is designed to work in sync. Machines move almost like they are part of a rhythm, and every component is built to match exact dimensions. On the surface, everything looks efficient and well-organized. But behind this smooth operation, there is one silent factor that often reduces productivity rework.

Rework doesn’t always happen because of a major failure. In many cases, it starts with small variations in machine performance, surface finish quality, or dimensional accuracy. These small inconsistencies might not seem serious at first, but over time they add up. The result is wasted production time, increased labor effort, and sometimes delayed deliveries. Many manufacturers try to fix this by upgrading machines or adjusting processes. However, choosing the right PCD grewing tool supplier can make a big difference in controlling automotive rework and maintaining stable production performance.

High-quality PCD cutting tools are not just another part of the manufacturing setup. They directly influence cutting precision, tool life, and surface finish quality. When the right supplier supports production with consistent tool quality and technical expertise, manufacturers can reduce variation, improve output quality, and achieve more predictable production results.

Why automotive rework is more expensive than it appears

In the assembly of automobiles, for instance, any minute dimensional deviation can bring an entire assembly process to a halt. If a machined part does not meet specifications, it will require re-verification, re-working, or replacement. These processes require valuable time, manpower, and machine hours.

The concealed quantity of rework waste affects an entire production procedure. Workers stop mid-process to examine elements, distribution schedules change, as well as operational pressures build up. Eventually, these types of occurrences cause an overall slowing down of work. Working with an effective PCD growing tool provider can assist you in preventing these problems before they start by ensuring that stability is present from the initial cut. Uniform PCD cutting tools minimize variation, which allows businesses to instead focus on seamless production.

The connection between tooling quality and repeatable machining

Repeatability is the heart of automotive manufacturing. Producing one perfect component is not enough; the same precision must be maintained across thousands of cycles. This level of consistency depends heavily on the quality of the cutting solution.

A trusted PCD grewing tool supplier designs tools with controlled geometry, strong wear resistance, and stable cutting performance. These characteristics allow PCD cutting tools to maintain dimensional accuracy for longer production runs. When tooling remains consistent, machining results remain consistent as well. This direct relationship between tool quality and production stability is why supplier selection matters just as much as machine capability.

How poor tooling support leads to recurring rework

When tooling is inconsistent or wears unpredictably, operators are forced to compensate. They may slow cutting speeds, increase inspection frequency, or replace tools earlier than necessary. While these actions protect part quality, they reduce efficiency and increase cost.

An experienced PCD grewing tool supplier provides more than just tools. They deliver engineering guidance, application knowledge, and performance reliability. High-quality PCD cutting tools supported by proper technical understanding help eliminate the cycle of adjustment and correction that leads to repeated automotive rework.

Surface finish and dimensional control in automotive parts

Automotive components demand extremely smooth finishes and tight tolerances. Imperfect surfaces can affect sealing, friction, and long-term durability. If the finish is inconsistent, additional polishing or grinding becomes necessary, adding more time to production.

Precision-engineered PCD cutting tools help create clean, accurate surfaces directly during machining. When supplied by a dependable PCD grewing tool supplier, these tools maintain sharp cutting edges and stable performance across extended cycles. The result is fewer secondary operations and a faster path from machining to assembly.

Tool life stability and production confidence

Unpredictable tool wear is one of the biggest causes of machining uncertainty. If a tool fails suddenly, production stops and scrap risk increases. To avoid this, operators often replace tools too early, which increases tooling cost.

Working with a proven PCD grewing tool supplier ensures access to PCD cutting tools designed for gradual, predictable wear. This stability allows planned tool replacement instead of emergency stoppages. As confidence in tool life grows, machines can run longer without interruption, improving both productivity and planning accuracy.

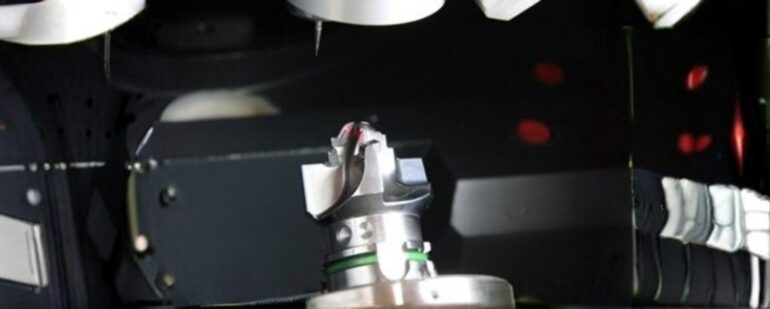

Supporting automation in modern automotive plants

Automation is now central to automotive manufacturing. Robotic systems and CNC lines are designed to run continuously with minimal supervision. For automation to succeed, tooling must remain reliable for long, uninterrupted cycles.

A knowledgeable PCD grewing tool supplier understands the demands of automated environments and develops PCD cutting tools capable of maintaining precision under continuous operation. Reliable tooling ensures that automated systems deliver consistent results without unexpected downtime, making automation truly efficient rather than risky.

Beyond price: evaluating true supplier value

Many purchasing decisions focus heavily on initial cost. While price is important, it does not reflect the full impact of tooling on production efficiency. Lower-cost tools that cause rework, downtime, or early replacement often become more expensive over time.

The real value of a PCD grewing tool supplier lies in long-term performance. Durable PCD cutting tools, reduced scrap, stable machining, and technical support all contribute to lower total production cost. When viewed from this broader perspective, supplier quality becomes a strategic investment rather than a simple purchase decision.

Collaboration between manufacturers and tooling experts

The most successful automotive operations treat tooling suppliers as technical partners rather than just vendors. Close collaboration allows machining challenges to be solved quickly and processes to be optimized continuously.

An experienced PCD grewing tool supplier works alongside engineers to refine cutting parameters, improve tool geometry, and adapt PCD cutting tools to new materials or tighter tolerances. This cooperative approach strengthens long-term manufacturing performance and reduces the likelihood of recurring rework.

Preparing for the future of automotive machining

Automotive technology is evolving rapidly, with lightweight materials, electric vehicle components, and stricter efficiency standards shaping production requirements. These changes demand even greater machining precision and reliability.

Forward-thinking manufacturers rely on an innovative PCD grewing tool supplier to stay prepared for these shifts. Advanced PCD cutting tools designed for modern materials and high-speed machining help ensure that production systems remain competitive as industry expectations continue to rise.

Conclusion

Automotive rework processes rarely begin with a catastrophic failure. Instead, they tend to originate with minor differences that accumulate over time, eating away at overall efficiency and trust. To do so requires looking beyond machine parameters, instead identifying qualities of a cutting solution.

The selection of a proper PCD growing tool supplier represents one of the most effective ways for manufacturers to prevent rework from starting at all. With the use of PCD cutting tools, manufacturers can obtain consistent machining, consistent tool performance, and improved surface finish.

Its use in the automotive industry today means success is only achievable through repeatability, precision, and trust in every machining operation. The right supplier partnership can turn a routine purchasing decision into a significant efficiency and performance driver.