PCD Inserts vs Carbide Inserts: Which Is Better for Precision Cutting?

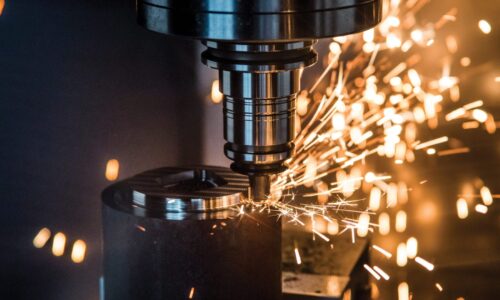

Precision cutting is no longer just a competitive advantage, it’s a necessity. As machining tolerances become tighter and customer expectations rise, manufacturers must carefully select cutting tools that deliver consistency, accuracy, and long-term efficiency. Among the most commonly debated options are PCD Inserts vs Carbide Inserts. Both are well-established solutions in modern machining, yet they serve very different purposes when it comes to precision.

Choosing the wrong insert can lead to poor surface finish, rapid tool wear, and increased production costs. Choosing the right one can transform productivity and machining stability. In this guide, we’ll take an in-depth look at how each performs and which option is truly better for precision cutting.

What Makes Precision Cutting So Critical?

Precision cutting goes far beyond simply shaping a component. It directly impacts dimensional accuracy, surface quality, assembly fit, and overall product performance. In industries such as automotive, aerospace, electronics, and medical manufacturing, even the smallest deviation can lead to rejection or failure.

To achieve reliable precision, cutting tools must maintain a sharp edge, resist wear, and perform consistently throughout long production cycles. This is where the comparison between PCD Inserts and carbide tools becomes especially important.

Understanding PCD Inserts

PCD Inserts are manufactured using polycrystalline diamond, created by sintering diamond particles under extremely high pressure and temperature. Diamond is one of the hardest materials known, making these inserts exceptionally wear resistant.

The biggest advantage of PCD Inserts lies in their ability to maintain edge sharpness for an extended period. Unlike traditional tools, they experience minimal edge breakdown, which helps maintain consistent cutting geometry. This stability is a major contributor to high-precision results, especially in demanding applications.

Because of their diamond structure, PCD Inserts also generate less friction during cutting. Lower friction means reduced heat, minimal deformation of the workpiece, and superior surface finishes.

Understanding Carbide Inserts

Carbide tools are made from tungsten carbide particles bonded with a metallic binder. Over the years, carbide technology has evolved significantly, offering various grades and coatings to improve performance.

Carbide Inserts are known for their toughness and versatility. They can handle interrupted cuts, higher impact forces, and a wide range of materials. This makes them a popular choice for general-purpose machining and roughing operations.

However, when it comes to ultra-precision cutting, carbide tools can face limitations. Even with advanced coatings, carbide edges tend to wear faster compared to diamond-based solutions, which can affect dimensional accuracy over time.

Material Compatibility: A Key Differentiator

Material selection plays a decisive role in choosing between these two insert types.

PCD Inserts are ideal for machining:

- Aluminum and aluminum alloys

- Copper, brass, and bronze

- Graphite

- Carbon fiber composites

- Reinforced plastics

These materials are often abrasive, and PCD Inserts handle them effortlessly while delivering exceptional surface finishes.

On the other hand, Carbide Inserts perform better with:

- Carbon steel

- Alloy steel

- Stainless steel

- Cast iron

Diamond-based tools are generally not suitable for ferrous materials due to chemical reactions at high temperatures, which is where carbide remains the safer option.

Precision and Surface Finish Comparison

One of the most noticeable differences between the two is surface finish quality.

PCD Inserts produce extremely smooth surfaces, often achieving near-mirror finishes. This reduces or even eliminates the need for secondary operations like polishing or grinding. For manufacturers focused on tight tolerances and aesthetic quality, this advantage is significant.

Additionally, the consistent edge retention of PCD Inserts ensures that surface finish remains uniform throughout the entire production run.

In contrast, Carbide Inserts may deliver acceptable finishes initially, but as wear progresses, surface quality can deteriorate. This makes frequent tool changes necessary to maintain precision.

Tool Life and Wear Resistance

Tool life directly affects productivity and cost efficiency.

PCD Inserts offer dramatically longer tool life often several times longer than carbide tools when machining non-ferrous materials. Their resistance to abrasion allows them to operate continuously without losing cutting efficiency.

While Carbide Inserts are durable, they wear faster in abrasive applications. Frequent tool replacements increase downtime and can introduce variability into the machining process.

For high-volume precision production, longer tool life translates into better consistency and lower long-term costs.

Cutting Speed and Thermal Stability

Precision machining often requires higher cutting speeds to meet production targets. PCD Inserts perform exceptionally well at high speeds due to their thermal stability and low coefficient of friction.

Reduced heat generation helps maintain dimensional accuracy and prevents thermal distortion of both tool and workpiece. This stability is crucial for components requiring micron-level tolerances.

Carbide Inserts, while capable of handling moderate to high speeds, generate more heat. Over extended cycles, this can impact tool life and machining accuracy.

Cost Considerations: Short-Term vs Long-Term

One common concern with PCD Inserts is their higher upfront cost. However, focusing only on purchase price can be misleading.

Because PCD Inserts last significantly longer and reduce machine downtime, their cost per component is often lower in high-volume applications. Fewer tool changes also improve workflow efficiency and reduce labor costs.

Carbide Inserts are more affordable initially and easier to replace. For small batch production, prototyping, or applications involving steel, carbide remains a cost-effective solution.

Stability and Vibration Control

Vibration is a major enemy of precision cutting. Even minor vibrations can lead to chatter marks, poor surface finish, and dimensional inconsistencies.

Thanks to their sharp cutting edges and smooth cutting action, PCD Inserts significantly reduce vibration. This results in better stability, especially in high-speed or long-cycle machining.

While Carbide Inserts can be stable, they are more susceptible to vibration as wear progresses, particularly in demanding precision operations.

Application-Based Decision Making

To choose the right insert, manufacturers should evaluate the specific application rather than relying on general assumptions.

Choose PCD Inserts when:

- Machining non-ferrous or abrasive materials

- High surface finish is critical

- Long production runs demand consistent accuracy

- Tool change downtime must be minimized

Choose Carbide Inserts when:

- Machining steel or cast iron

- Performing interrupted or impact-heavy cuts

- Flexibility across materials is required

- Budget constraints are a priority

Industry Use Cases

In automotive manufacturing, PCD Inserts are widely used for machining aluminum engine blocks and transmission components due to their speed and consistency.

In aerospace and electronics, precision and surface integrity are paramount, making diamond-based tools a preferred choice.

Meanwhile, Carbide Inserts dominate steel machining in heavy engineering, construction equipment, and general-purpose manufacturing environments.

Which Is Better for Precision Cutting?

When the focus is purely on precision cutting, PCD Inserts emerge as the superior choice. Their exceptional wear resistance, superior surface finish, vibration control, and dimensional stability make them ideal for high-accuracy applications involving non-ferrous materials.

However, Carbide Inserts still play a vital role in machining ferrous materials and versatile shop-floor operations. They offer toughness, adaptability, and cost efficiency where diamond tools are not suitable.