Grinding Quality Dropping? Roller Dressers Are Often the Missing Fix

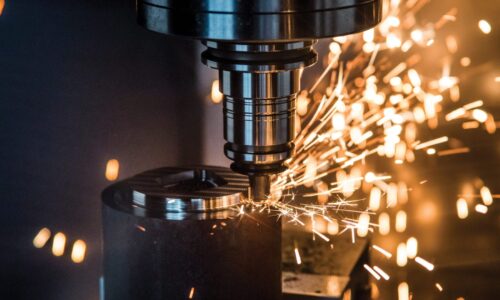

Roller Dressers play a critical role in maintaining grinding stability, even when everything on the shop floor appears normal. Walk into a grinding operation that was running well, and people might sense something before anyone says anything. Machines might still be running, sparks flying, and product still being made. It could be that people are stopping to check measurements more than needed, the surface of the product looks different each batch, or more adjustments have to be made to each product than before. It’s not necessarily bad grinding, just not as good as it used to be.

Such a condition is very common in manufacturing. Most of the time, it is not due to a malfunctioning equipment or a mistake by an equipment operator. Most often, the reason behind that condition remains quietly behind the scenes every day. The reason behind that condition is the condition of the Roller Dressers.

Grinding quality, as can be seen, is an issue of grinding quality consistency. While consistency diminishes, productivity, as well as confidence, economically decline as well. Knowing the role, the need, the function, as well as the tools, like the Multipoint Diamond Dressers, which aid them, can allow manufacturers an opportunity to solve grinding before the costly failure ensues.

Why Grinding Quality Matters More Than People Realize

Manufacture is often completed at grinding. By the time a part reaches grinding, much of the work and cost has already been factored into it. If grinding quality drops at this stage, then the loss is that much bigger than in an earlier process.

Good quality grinding ensures a component meets size, shape, and surface finish requirements. Grinding quality affects component fits, durability, and the reliability found in the real world. Poor grinding quality generates rework, scrap, and delays, not to mention unhappy customers.

When grinding results start changing without obvious reasons, it starts to create stress on the shop floor. Operators lose trust in the process. Supervisors add more inspections. The machines are slowed down in order to “play safe.” All this reduces output, with very often the root cause lying with worn or poorly maintained Roller Dressers.

The grinding wheel is only as good as its dressing

Many people focus on the grinding machine itself. Speed, feed, coolant, and material all matter. But none of these can deliver stable results if the grinding wheel is not in good condition.

Grinding wheels wear continuously. As they cut material, abrasive grains become dull, clogged, or damaged. A worn wheel does not cut cleanly it rubs, generates heat, and causes surface problems.

This is where Roller Dressers play a key role. Their main job is to restore the grinding wheel so it can cut properly again. They shape the wheel, open fresh abrasive grains, and ensure the wheel surface stays consistent.

Without effective Roller Dressers, even the best grinding machine cannot maintain quality for long.

What Roller Dressers actually do in daily grinding

Roller Dressers are designed to condition grinding wheels with high accuracy. They dress the wheel profile, maintain geometry, and ensure uniform cutting behavior across the wheel surface.

When Roller Dressers work properly, the grinding wheel cuts smoothly, heat stays under control, and results remain repeatable. Operators notice stable sparks, predictable sound, and consistent surface finish.

But Roller Dressers are not permanent tools. They wear slowly over time. And this slow wear is exactly why grinding quality drops without obvious warning.

How worn Roller Dressers quietly reduce grinding quality

One of the biggest challenges with Roller Dressers is that they do not fail suddenly. Their performance decreases little by little.

At first, the wheel still looks dressed. Parts still pass inspection. But small changes begin to appear. Wheel shape becomes slightly inaccurate. Abrasive grains are not exposed evenly. Cutting forces increase.

These small issues add up. Surface finish starts to vary. Heat increases. Dressing frequency goes up. Operators begin making manual corrections. Grinding quality slowly drops and nobody can point to a single cause.

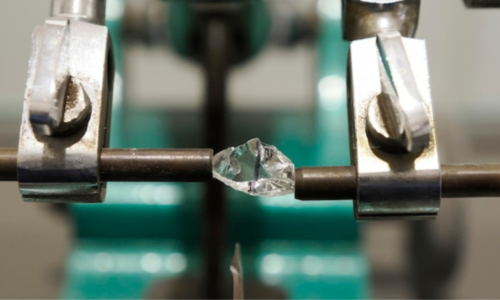

This is where support tools like the Multipoint Diamond Dresser become important, helping maintain dressing accuracy and wheel condition.

Why heat is a warning sign you should not ignore

Excess heat is one of the clearest signs of grinding trouble. When a wheel is properly dressed, it cuts cleanly and removes material efficiently. When dressing quality is poor, the wheel rubs instead of cuts.

This rubbing creates friction and heat. Heat causes surface burns, micro-cracks, and dimensional distortion. It also shortens wheel life and damages parts.

Worn Roller Dressers often fail to open the wheel surface properly. As a result, heat builds up faster than expected. Using precise tools such as the Multipoint Diamond Dresser helps restore sharpness and reduce heat-related problems.

Inconsistent wheel wear leads to unstable results

A grinding wheel should wear evenly. Uneven wear changes wheel shape during operation, which affects size and finish.

When Roller Dressers are worn or inaccurate, some areas of the wheel work harder than others. This causes imbalance, vibration, and changing grinding behavior.

Properly maintained Roller Dressers, supported by a Multipoint Diamond Dresser, help ensure even wheel wear. This leads to longer wheel life, fewer corrections, and stable grinding quality over time.

Operator confidence depends on dressing quality

Grinding operators develop a feel for stable processes. They know when a machine sounds right and when something feels off.

When grinding quality starts changing, confidence drops. Operators slow feeds, check parts more often, and stop machines frequently. These actions protect quality but reduce productivity.

Restoring confidence often starts with fixing the basics. Accurate wheel dressing using reliable Roller Dressers gives operators predictable results again. Precision support from a Multipoint Diamond Dresser helps maintain that predictability.

Modern manufacturing puts more pressure on dressers

Today’s manufacturing environment demands tighter tolerances, higher speeds, and harder materials. Grinding processes are pushed harder than ever before.

Under these conditions, worn Roller Dressers cause problems much faster than they used to. What once took weeks to notice may now appear within days.

Regular inspection, proper maintenance, and timely replacement of Roller Dressers are no longer optional. Supporting them with tools like the Multipoint Diamond Dresser helps meet modern production demands without sacrificing quality.

The hidden costs of ignoring Roller Dressers

Many manufacturers delay replacing or servicing Roller Dressers to save money. Unfortunately, this often leads to higher costs in the long run.

Poor dressing leads to increased scrap, rework, wheel consumption, and energy use. Downtime increases as machines need more adjustments. Delivery schedules suffer.

Investing in quality Roller Dressers and precision tools such as the Multipoint Diamond Dresser reduces these hidden losses and improves overall efficiency.

Grinding consistency starts before grinding begins

Grinding quality does not start at the workpiece. It starts with how well the grinding wheel is prepared.

When Roller Dressers are accurate and well-maintained, the wheel performs as expected. When they are worn, inconsistency becomes unavoidable.

Using a Multipoint Diamond Dresser alongside Roller Dressers ensures the wheel is always in the right condition before grinding even begins.

Simple steps to restore grinding quality

Improving grinding quality does not always require big changes. Often, it starts with simple actions.

Checking the condition of Roller Dressers, monitoring dressing results, adjusting dressing parameters, and using precision tools like the Multipoint Diamond Dresser can quickly bring grinding quality back under control.

These steps improve stability, reduce heat, and extend tool life.

Conclusion

When grinding quality starts dropping, the problem is often closer than it seems. Worn Roller Dressers quietly affect wheel condition, cutting behavior, and process stability.

They may not attract attention, but their impact is huge. Grinding quality, productivity, and confidence on the shop floor all depend on them.

By maintaining Roller Dressers properly and supporting them with precision solutions like the Multipoint Diamond Dresser, manufacturers can restore consistency and achieve reliable grinding performance.

In grinding, quality is never an accident. It starts with the tools that prepare the wheel and getting that step right makes all the difference.