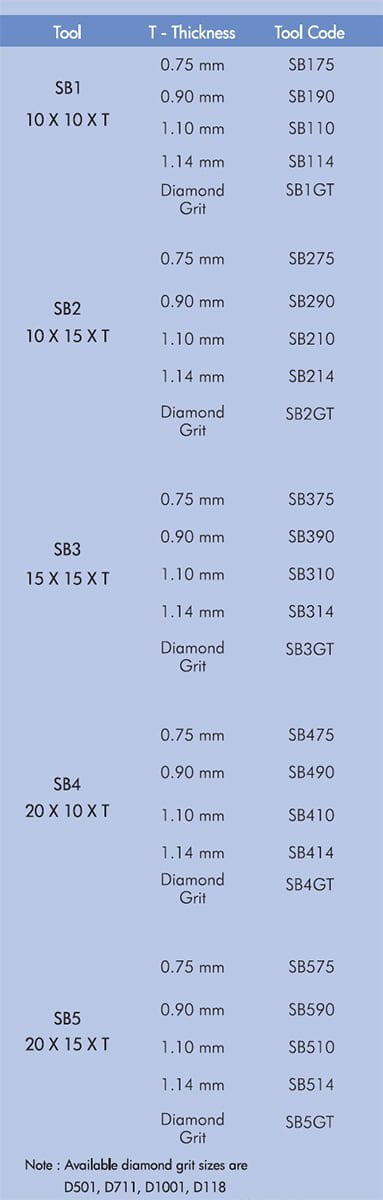

Needle Blade Dresser

We are Manufacturer, Exporter, Supplier of Blade Type Diamond Dressers, and our set up is situated in Aurangabad, Maharashtra, India. In this Blade Type Diamond Dressers, Needle shaped diamonds are carefully selected and set manually in an appropriate pattern in several layers. The uniform thickness of the diamond needles and setting pattern ensure a constant effective width of the blade over the whole tool life to get constantly high surface finish.

Grit Type

In this Blade Type Diamond Dressers, blocky diamond grains are set according to an appropriate pattern. This blade is made for extremely long service life and used in a precision dressing application.

Advantages of the Blade Type Diamond Dressers

- No resetting or re – lapping required.

- Reduce inventory, cost cutting up to 40 to 50%.

- These tools can be used completely without any requirement of maintenance.

To get the maximum tool life

- The mounting must be vibration free, with the clamping length as short as possible.

- For the straight dressing operation place the blade tool perpendicular to the wheel axis.

- Always use plenty of coolant during the dressing operation, which increases the tool life.

- Depth of cut should be 0.01 to 0.03 mm.

- Blade tool should be mounted in the holder perfectly.

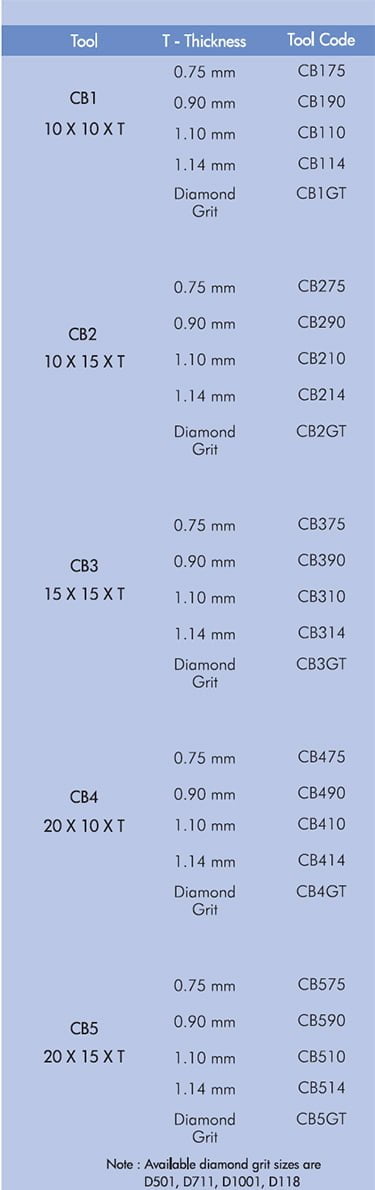

Needle Blade Dresser

Grit Type

In this Blade Type Diamond Dressers, blocky diamond grains are set according to an appropriate pattern. This blade is made for extremely long service life and used in a precision dressing application.

Advantages of the Blade Type Diamond Dressers

- No resetting or re – lapping required.

- Reduce inventory, cost cutting up to 40 to 50%.

- These tools can be used completely without any requirement of maintenance.

To get the maximum tool life

- The mounting must be vibration free, with the clamping length as short as possible.

- For the straight dressing operation place the blade tool perpendicular to the wheel axis.

- Always use plenty of coolant during the dressing operation, which increases the tool life.

- Depth of cut should be 0.01 to 0.03 mm.

- Blade tool should be mounted in the holder perfectly.